Using a stiff brush, for example, a toothbrush,

remove any build up of grease, wax, dust, and

dirt. Also remove a similar build up within the

blower housing itself.

4.

Clean the ventline elbow next to the unit, first

by removing the elbow and then cleaning with

warm soap water or a stiff brush.

5.

The interior of the housing should be cleaned

every 90 days of bits and pieces of paper which

fall to the exterior of the incinerator chamber. To

do this, remove the four screws holding the top

and bowl, then lifting the top section out of the

way, thereby exposing the interior of the

housing. Remove the paper pieces.

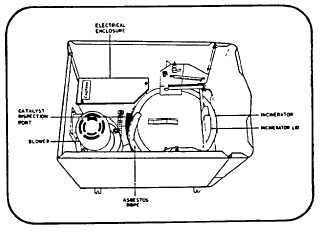

PARTS REPLACEMENT

Before replacing any part or making any continuity

measurements, voltage must be removed from the unit.

Remove ashpan.

Remove top and bowl section.

For electrical parts inspection, remove the cover from

the control box. All electrical parts are accessible.

Inspect for loose wiring or wiring harness holding the

relay closed.

HEATER REPLACEMENT.

Disconnect the terminals of the heater leads by first

removing the hex locknuts. Carefully remove the

asbestos sealing rope about the heater cold ends

coming through the wall of the incinerator chamber as

this packing rope will be reused. Remove the 1/4 inch

bolts holding the heater brackets in place so that the

brackets and heater are now free to be removed through

the front of the incinerator chamber. Install the new

heater in exact reverse order.

CAUTION: When replacing the hex locknuts on the

heater terminals, use two end wrenches, one for the

locknut and one for the terminal stud coming from

the heater. Be sure that the locknut is tight

against the terminal without twisting the heater stud

and breaking the seal of the heater.

Good practice is to replace the control thermostat

(L-290) along with a new heater in order to insure proper

incineration control.

THERMOSTAT REPLACEMENT

Both control thermostat (L-290) and blower thermostat

(F-140) are located in the lower portion of the incinerator

chamber to the rear of the ashpan. Both are replaced

from the back by removing two screws. Replacement

thermostats are furnished with the necessary wiring and

terminals. When replacing thermostats make certain to

use the same number of gaskets under the mounting

flange.

CATALYST REPLACEMENT

The catalyst inspection port, located at the upper rear

portion of the incinerator chamber, is closed by means of

an asbestos rope. To inspect the level of catalyst,

remove the rope. If the level of the catalyst is quite low,

say 1 inch or more below the level of the top of the port,

fill the port with replacement catalyst, working it to the

left and right beyond the extremes of the port by means

of a screwdriver to insure that all parts of the catalyst

container are full of the catalyst. Use sufficient catalyst

to fill all parts as well as the port itself to within about 1/4

of an inch of the top of the port. Then replace the

asbestos rope, packing it securely in place.

6