DECKMASTER

MOUNTING THE NEW HARDWARE

•1.

Re-check the series number on the control

feedback link to ensure that it is compatible with

the pump. If the control is In MCV106AX9XX

(i.e., control less linkage assembly), follow the

procedure outlined below to install the linkage:

A.

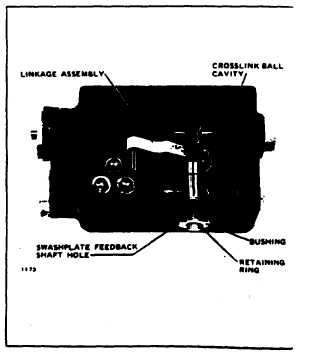

Unscrew the bushing, using care not to

damage its O-ring. See Figure 6.

B.

Install the new linkage assembly shaft

through the swashplate feedback shaft

hole. Place the ball in the crosslink ball

cavity.

C.

Lubricate the shaft O-ring and replace the

bushing over the shaft. Torque to the

body (10-15 foot-pounds) so that the

feedback

shaft

extends

through

the

bushing.

D.

Install the retaining ring in the groove on

the shaft.

•2.

Align one end of the replacement drag link with

the holes in the swashplate link arms.

•3.

Insert the press fit pin through the case drain

port to trap the drag link in the swashplate

clevis. It will be necessary to tap the pin into

place until the head of the pin is flush to the

clevis

•4.

Install the retaining ring by forcing it onto the

tapered end of the pin until it locks into the

recess on the pin shaft. Again, use caution not

to drop any components into the pump housing.

•5.

One .042 inch diameter orifice must be installed

in the supply passage on pressure override-

compatible valves. (See Ordering Information.)

For all others. a .042-inch diameter orifice may

be installed in the supply passage if reduced

swashplate response is desired.

•6.

Engage the pin on the control in the drag link

and swing the control into place against the

pump housing. The drag link should be on the

cylinder block side of the swashplate. Install the

seven mounting screws and tighten to 10-11

footpounds of torque.

•7.

Connect the pipe or tubing from the control

handle into the C1 and C2 ports (9/16-18 UNF

threads per SAE J514}. Phasing of the HDC is

such that a pressure rise at the C2 port causes a

pressure rise at the A output port of the pump,

given a clockwise

pump prime mover

rotation as viewed into the input shaft.

PUMP NEUTRAL ADJUSTMENT

USE THE FOLLOWING PROCEDURE TO BRING THE

PUMP

TO

NEUTRAL

ONCE

THE

HYDRAULIC

DISPLACEMENT CONTROL HAS BEEN MOUNTED.

•1.

Install a 300 psi gauge into the charge pressure

gauge port on the pump. See Figure 7.

•2.

Using a 9/16-inch wrench. loosen the hex lock

nut on the null adjustment screw. See Figure 1.

To adjust neutral requires operating

the pump. Take the necessary safety

precautions

such

as

having

necessary personnel stand away

from the machine Maximum system

pressure may occur upon start up,

and the machine may move. Ensure

that the operator is not in a position

to be injured should the machine

move.

•3.

Set the hydraulic control handle to

neutral.

•4.

Start the prime mover and run at low idle.

•5.

Warm the system up for several minutes

to bleed air.

•6.

Slowly increase the prime mover speed to

rated rpm.

FIGURE 7. Location of pump ports.

PUMP NEUTRAL ADJUSTMENT