MINOR REPAIRS

5.

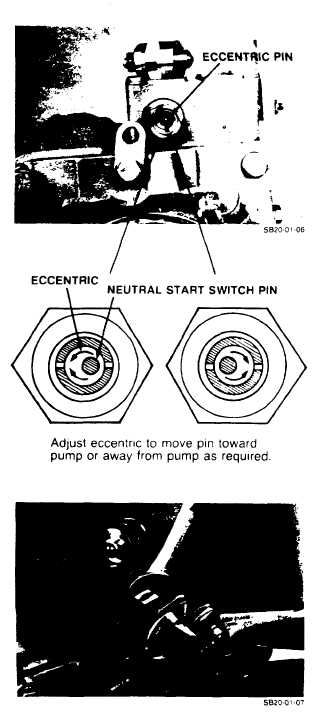

If it was necessary to rotate the control handle

clockwise to obtain continuity, turn the eccentric

adjustment to move the pin down (or toward the

pump). If a counterclockwise rotation of the

handle was necessary to obtain continuity,

rotate the eccentric to move the pin up (or away

from the pump). Only a small amount of

adjustment in either direction is needed to

center the pin in the internal mechanism cam

slot.

Turn the eccentric a maximum of 14 of a turn

while frequently stopping to check maximum pin

depth into the eccentric collar. In most cases it

can be determined that the pin has engaged in

the slot, either by feel or depth gauge. within

the first 1/4 turn.

6.

While holding the eccentric in place, tighten

eccentric locknut to 20-35 ft. lbs. Reinstall the

switch as outlined in the Neutral Start Switch

replacement and adjustment portion of this

manual.

7.

Repeat steps 3 and 4 to determine whether

additional

adjustment

of

the

eccentric

is

necessary.

If further adjustment is required, continue

rotation up to 1,4 additional turn.

CAUTION

Do not exceed 1/2 turn total or 1800

from the initial pin position. Doing

so will turn the eccentric into or out

of

the

housing

beyond

specifications.

If too much adjustment was made, turn the eccentric 1/8

turn in the opposite direction.

Again, install the switch and check for continuity.

Page 34