MINOR REPAIRS

CAUTION

The following procedure requires that

steps be taken to disable the machine

in the event the pump should go into

stroke (raise drive wheels off ground,

etc.).

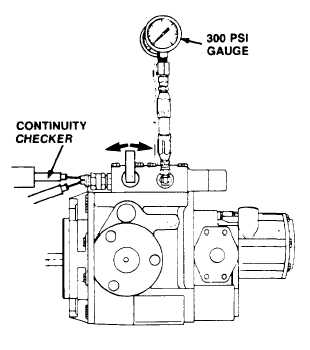

8.

Connect the electrical leads from the machine

starter relay to the electrical connections on the

switch.

9.

Start the prime mover and operate at normal

speed.

10.

Note pressure reading on the gauges at this time.

The reading should be noted as base pressure.

11.

Slowly move the control handle in one direction

while observing the pressure gauge and the

continuity checker. Continuity must be broken

before the gauge pressure increases more than 12

PSI from the base pressure obtained at neutral.

12.

Slowly move the control handle in the opposite

direction. Again, continuity must be broken before

the gauge pressure increases more than 12 PSI

from base pressure.

13.

Continuity must again be verified when the control

is returned to neutral.

If continuity is not broken at base pressure +0-12

PSI in either direction, stop the prime mover and

readjust the eccentric as described in step 5. If the

pressure difference is equal in each direction but

greater than 12 PSI loosen the switch locknut and

turn the switch in 1/16 of a turn to increase the

sensitivity. Retighten the locknut and recheck

pressure differences and continuity.

14.

After verifying proper control and switch operation,

stop the prime mover. Remove the continuity

checker and pressure gauges. Install pressure port

plugs and torque to 10-20 ft. lbs. Install and

adjust, if necessary, the external control linkage.

Page 35