TM 55-1930-209-14&P-6

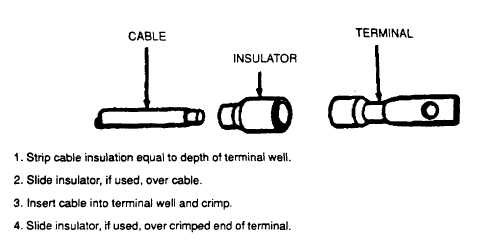

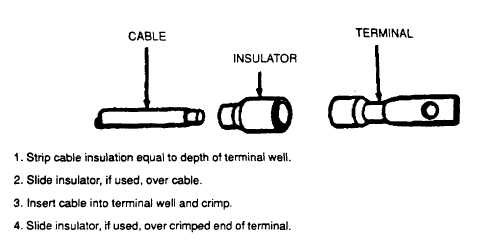

Figure 4-1. Replacement of Crimped Terminals

NOTE

Due to this vessel's mission and crew capabilities, maintenance normally assigned to

organizational level or higher echelons may be assigned to the crew by the Bargemaster.

4-7 Component. Component maintenance information is contained in the appendices under manufacturers' service

manual/instructions in Appendix B.

4-8 Shore discharge system. Lubrication and repair of the shore discharge system involving repair parts listed in TM

55-1930-209-14&P-18 are described herein.

WARNING

Shut down shore discharge system before attempting any repair. Be sure to open circuit breaker

P12 on switchboard. Redtag circuit breaker with: WARNING - DO NOT ACTIVATE. REPAIRS

BEING MADE."

CAUTION

Always cover open hydraulic lines and component ports to keep out dirt.

4-9 Lubrication

4-9.1 Hydraulic power unit. Use Gulf Harmony 46 AW or equivalent as recommended in Appendix B by the

manufacturer.

WARNING

Wear safety glasses. In case of eye contact, wash with lots of water. In case of skin contact,

wipe and then wash with soap and water.

4-9.1.1 Adding fluid. When reservoir oil level sight gauge (Figure 3-4) indicates hydraulic fluid level in reservoir is 80

percent or lower, add fluid as follows:

a.

Remove filler/breather cap.

b.

Clean filter.

c.

Add fluid until sight gauge indicates 100 percent full.

d.

Replace cap.

e.

Wipe clean reservoir and immediate area.

4-4