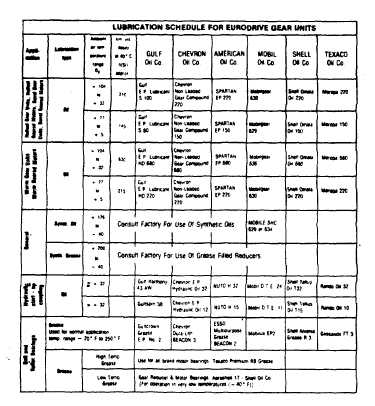

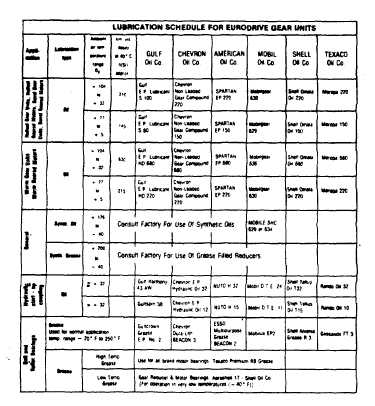

LUBRICATION INFORMATION

IMPORTANT

EURODRIVE recommended lubrication schedule should be

followed if possible. If any other lubricant is used please consult

with the factory about any harmful effects of certain lubricants or

applications.

LUBRICANTS

For recommended oil and grease see the lubrication schedule.

All gearunits supplied by EURODRIVE are shipped with oil and

grease. The units are ready to be operated after being properly

installed and aligned.

OIL LEVELS

The amount of oil in each gear unit depends on the mounting

position of the gear unit. The oil level can be checked by

removing the red painted oil plug. The oil level must be even

with the bottom of the threaded hole.

Note that the required oil level changes when the mounting

position is changed from the originally ordered position.

Check oil level required, on the different mountings, in the

catalog.

Please make sure that the plastic stop in the vent plug is

removed before operating the gear unit. This will assure us that

no pressure build up will take place inside the gear unit.

Gear units can only be operated in a non-ventilated condition

when approved by the factory.

MAINTENANCE OF GEARUNITS

All EURODRIVE units require a minimum of

maintenance.

For a long-life operation we suggest the

following:

1.

All oil levels and oil quality must be

checked every 5000 hours. If the oil is

contaminated, burned or waxed, change

the oil immediately and flush out the

box if necessary.

2.

Under normal operating conditions we

recommend an oil change every 10,000

hours of operation or 2 years.

3.

When a synthetic oil is used change the

oil every 40,000 hours or 4 years.

4.

Grease

packed

bearings

must

be

cleaned and regreased every 10,000

hours. The bearing grease area must

be filled to approximately 1/3 of the

available area to avoid overheating of

the bearing.

The above suggestions are however,

subject to change if the units are

running

in

high

temperature,

high

humidity or corrosive environments. If

any

of

these

situations

exist

the

lubricant may have to be changed more

frequently.

OVERHUNG LOAD

To prevent excessive loads on the input or

output shaft and bearings please make sure that

the load on the shafts does not exceed the

limitations of the gear unit.

Consult with the factory if necessary.

THE INSTALLATION OF A COUPLING,

SPROCKET, GEAR OR SHEAVE

When

installing one of the items listed above please

make sure that the proper tools or procedures

are used.

Do not hammer on the shafts.

Hammering on the shafts can cause brinelling of

the bearings and a considerable reduction in

bearing life.

Instead of "hammering on" the components we

suggest heating up the items if possible to

approximately 175°F. This will eliminate any

damage to the bearings.

It should be noted that the EURODRIVE units

with shafts up to 1-1/2" diameter are machined

to a tolerance of +.0000"; -.0005"; and the larger

diameter shafts are machined to a tolerance of

+.0000";-.0010".

5