MOTOR/BRAKE INFORMATION

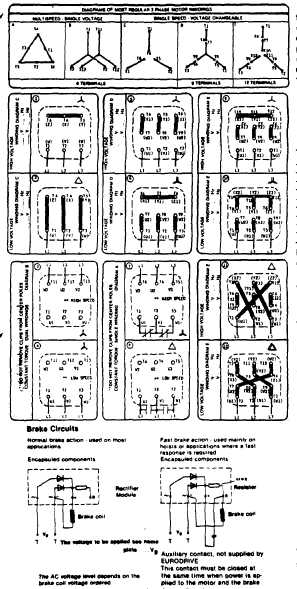

MOTOR CONNECTIONS

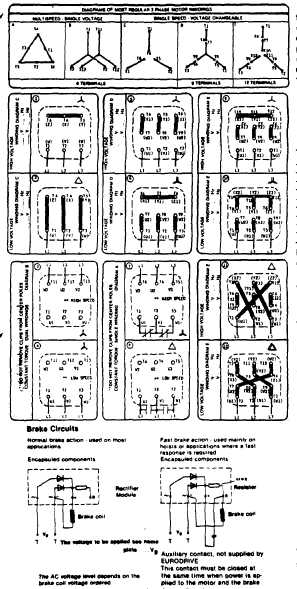

FAST BRAKE ACTION IS ESSENTIAL

FOR HOIST APPLICATIONS

The voltage VB must be applied and removed at the

same time as the power to the motor.

- Voltage to the rectifier energizes the brake coil and

releases the brake.

- Removal of the voltage VB de-energizes the brake

coil and allows the brake to be applied.

The AC voltage VB will be rectified to a DC level of 50%

of the AC voltage applied.

MECHANICAL PROPERTIES

EURODRIVE

gear

motors

are

designed

and

manufactured with totally enclosed fan cooled squirrel

cage

induction

motors

which

are

designed

for

continuous operation under difficult conditions. The

windings are protected with a special Insulating material

Class B equivalent or better. The brake motors

incorporate a DC disc brake and the supply is taken

from a half-wave rectifier mounted inside the motor

terminal box.

Motor Winding Connections

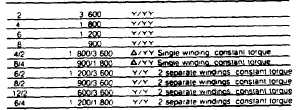

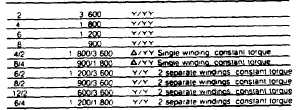

Number

Synchronous

Connection

of

speed

Poles

RPM

For voltages other than 2301460V, 60HZ; check decal in

conduit box.

BRAKE COIL VOLTAGES

Motors with dual voltage connections: 230/460V, 60HZ

will be supplied with a 230V brake coil. In each case,

whether the motor voltage is 230 or 460 VAC, the brake

rectifier is connected to T7-T8 where 230VAC will be

tapped oft the terminal block.

See motor connection diagram number 5 for 460VAC,

60HZ and number 6 for 230VAC, 60HZ power supplies.

For Brake Motors Operating On: 200V/208V, 575V,

60HZ or 220/380V, 415V, 50HZ, the above does not

apply. In all cases the brakes will be connected for the

requested operating voltage.

MAINTENANCE

The only maintenance, normally, required is to ensure

that the area between the cooling fins and the area

through which the air is drawn in the fan guard is kept

clean and that an audible check is made on the

bearings. If the motor is being overhauled the bearings

must be cleaned and repacked. If the motor has to

operate in moist or wet surroundings then it is very

important that on reassembly of the motor the end

shield tenons are coated with a sealing compound such

as loctite.

VOLTAGE

REGULATION --Motors

will

operate

successfully under the following conditions of voltage

and

frequency

variation,

but

not

necessarily

in

accordance with the standards established for operating

under rated conditions:

a. When the variation in voltage does not exceed 10%

above or below normal, with all phases balanced.

b. When the variation in frequency does not exceed 5%

above or below normal.

c. When the sum of the voltage and frequency

variations does not exceed 10% above or below normal

(provided the frequency variation does not exceed 5%).

7