TM 10-4320-317-13

(1)

Disconnect pumping assembly from tow vehicle. Refer to appropriate pumping assembly technical manual.

(2)

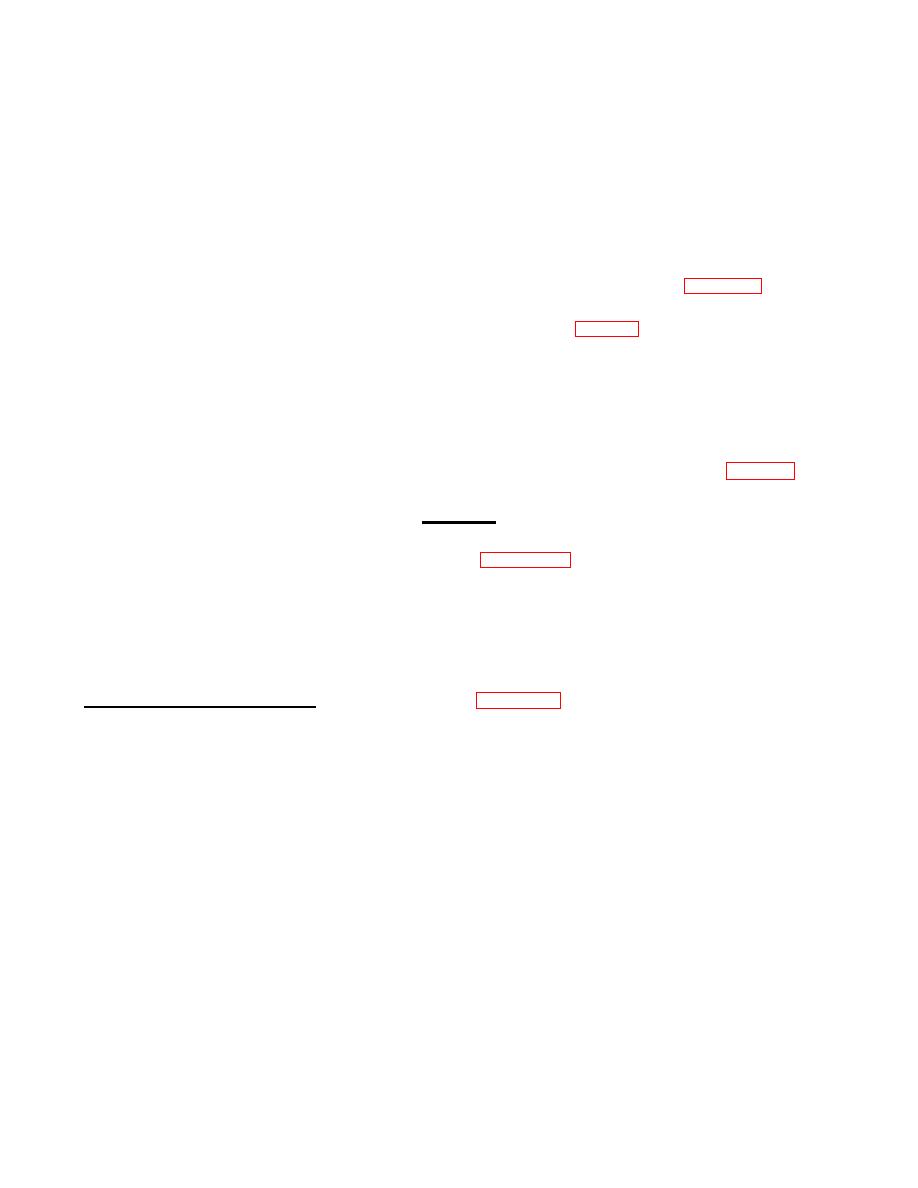

Remove plastic cap from suction port (1) on pump. Retain cap for movement or storage.

(3)

Locate 6 in. X 10 ft lengths of rigid-walled, wire reinforced suction hose (2) with quick-disconnect fittings.

CAUTION

To prevent leakage, close both cam arms at the same time.

Do not strike cam arms to close. Damage to couplings could result.

(4)

Connection suction hose (2) to suction port (1). Close cam arms.

(5)

Install 6-inch butterfly valve (3) on suction hose (2) with 6-inch boltless coupling (4) (para. 2-8.b). Set valve to

fully opened position.

(6)

Install additional 6-inch hose lengths (4) with boltless couplings (5) (para 2-8.b) to butterfly valve (3) until pump

is connected to water source.

(7)

Remove plastic cap from discharge port (7) on pump. Retain cap for movement or storage.

CAUTION

Make sure arrow on check valve points away from pump. Damage to pump may occur if pump

discharge is blocked.

(8)

Install 6-inch check valve (6) on pump discharge port (7) with 6-inch boltless coupling (8) (para. 2-8.b.). Install

valve with arrow pointing away from pump.

WARNING

Personal injury may result from high pressure water if pressure-relief valve faces butterfly valve.

Ensure pressure-relief valve is installed as shown in Figure 2-16 to avoid personal injury.

(9)

Install pressure-relief valve assembly (9) to 6-inch check valve (6) with 6-inch boltless coupling (10).

(10) Connect end of 10-mile segment collapsible hose (11) to pressure-relief valve assembly (9) with 6-inch boltless

coupling (12).

(11) Restrain hose manually until first 50 ft (15 m) of hose is in position. After 50 ft (15 m) of hose is in position, the

weight of the hose will hold line in place.

i. Assemble Boost Pumping Stations. Perform the following (Figure 2-17):

(1)

Disconnect pumping assembly from tow vehicle. Refer to applicable pumping assembly technical manual.

2-36