TM 10-4610-232-12

NOTE

Backwash air inlet solenoid failure will be noted by the absence of air flow noise at the

second backwash step. Another indication is that the air system air pressure gage does not

drop in pressure when backwashing.

(4)

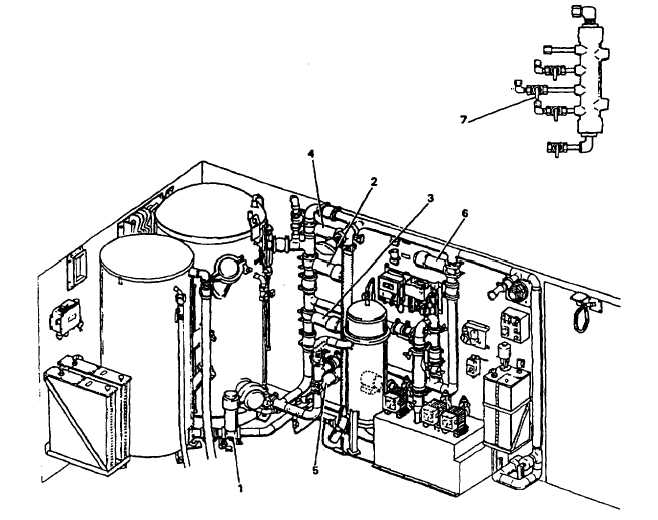

Air backwash valve. This backwash air inlet solenoid valve can be bypassed to allow a complete manual backwash

(Figure 2-75).

(a)

Close the backwash air block valve (1).

(b)

Disconnect the tubing (2) at both ends of the backwash valve (3).

(c)

Remove jumper tube (4) from storage box no. 3 (Figure 2-24).

(d)

Connect jumper tube (4, Figure 2-75) to free ends of disconnected tubing.

(e)

Partially open the backwash air block valve (1) during backwash. Air flow will be delivered. Watch that the system air

pressure gage does not drop below 150 psig (1034 kPa). Close backwash air block valve (1) if it does.

(5)

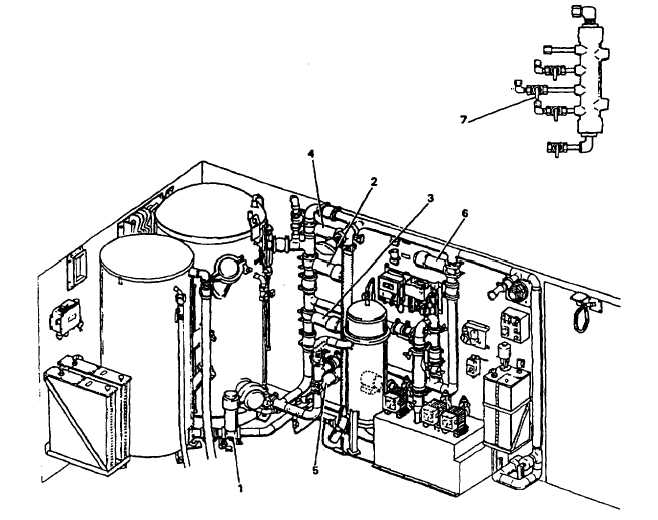

Filter Normal Valve Positions (Figure 2-76). Position the manually operated automatic valve(s) according to positions

listed below and then follow normal star-up procedures (para. 2-17).

Figure 2-76. Manually Operated Automatic Valve Position

(MODEL WTA-060 ONLY)

2-158 Change 12