TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

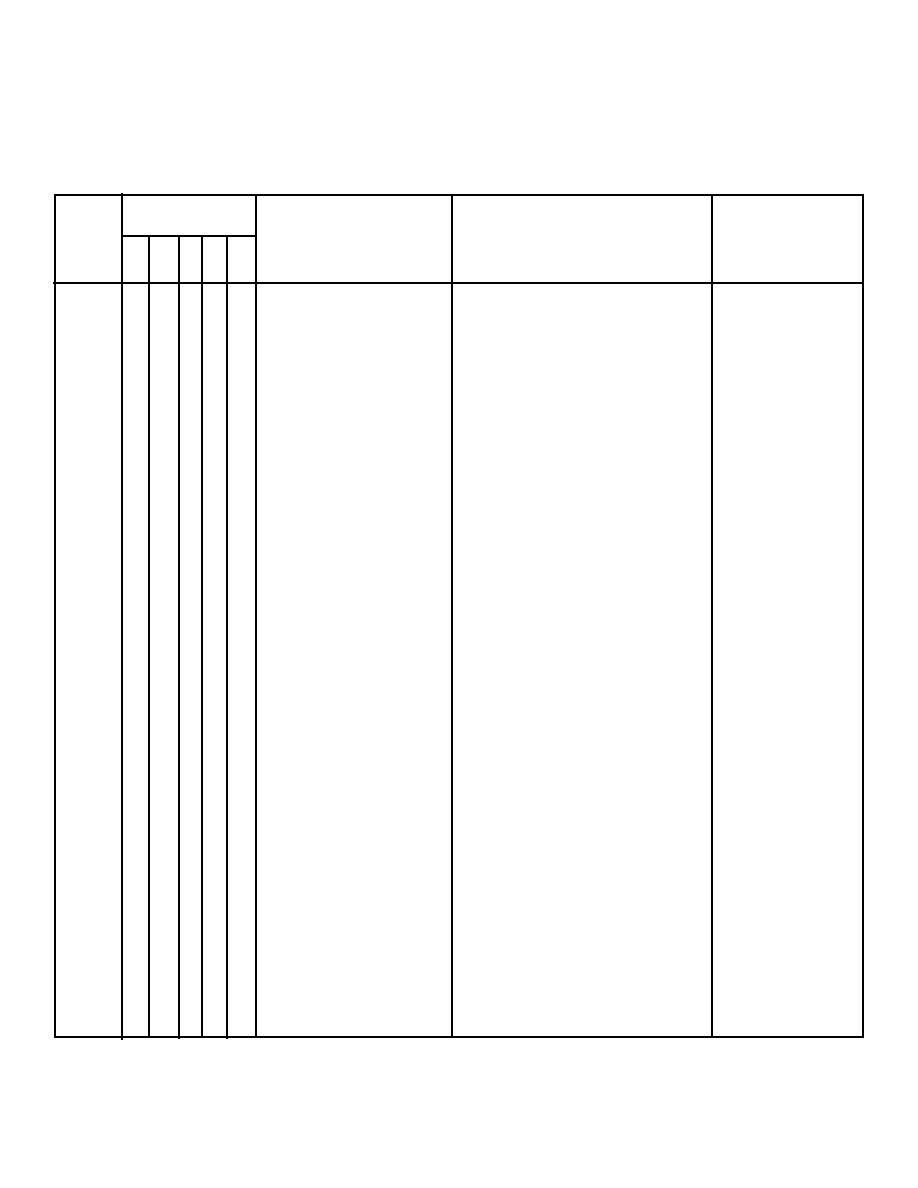

Table 2-2. (ARMY) Operator/Crew Preventive Maintenance Checks and Services (Trailer) - Continued

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

Item to be

Procedures

Equipment is

ITEM

Inspected

Check for and have repaired

not ready/

NO.

B

D

AWM

or adjusted as necessary.

available if:

7

Air hoses

Check for cracks, leaks, or other

Hoses broken or

damage.

leaking.

8

Air brake tubing,

Inspect for bends, dents, and

Parts badly dam-

reservoir, and

leaks which may interfere with

aged or leaking.

other components.

proper operation.

9

Air reservoir

Drain condensation by opening

Draincock broken or

draincock; close draincock after

corroded.

draining.

Check for broken or

corroded draincock.

10

Tires

Check for proper inflation (75

Tires flat or below

psi); be sure tires are not exces-

recommended pres-

sively worn. Check that all tires

sure.

are worn evenly.

11

Nuts

Make sure lug nuts on wheels

Any lug nuts miss-

and other equipment fasteners

ing.

have not worked loose. Check

that cap nuts are properly seated

and tight.

12

Axles, springs

Visually inspect all structural

Structural parts bro-

parts for excessive wear, corro-

ken.

sion, broken welds.

13

Trailer frame

Inspect for broken welds.

Welds broken.

14

Lunette

Inspect for loose or damaged

Lunette misaligned

bolts.

or loose.

15

Leveling jack

Check that cranks are in place on

cranks

support brackets.

16

ROWPU frame

Inspect for broken welds.

Welds broken.

2-19