TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

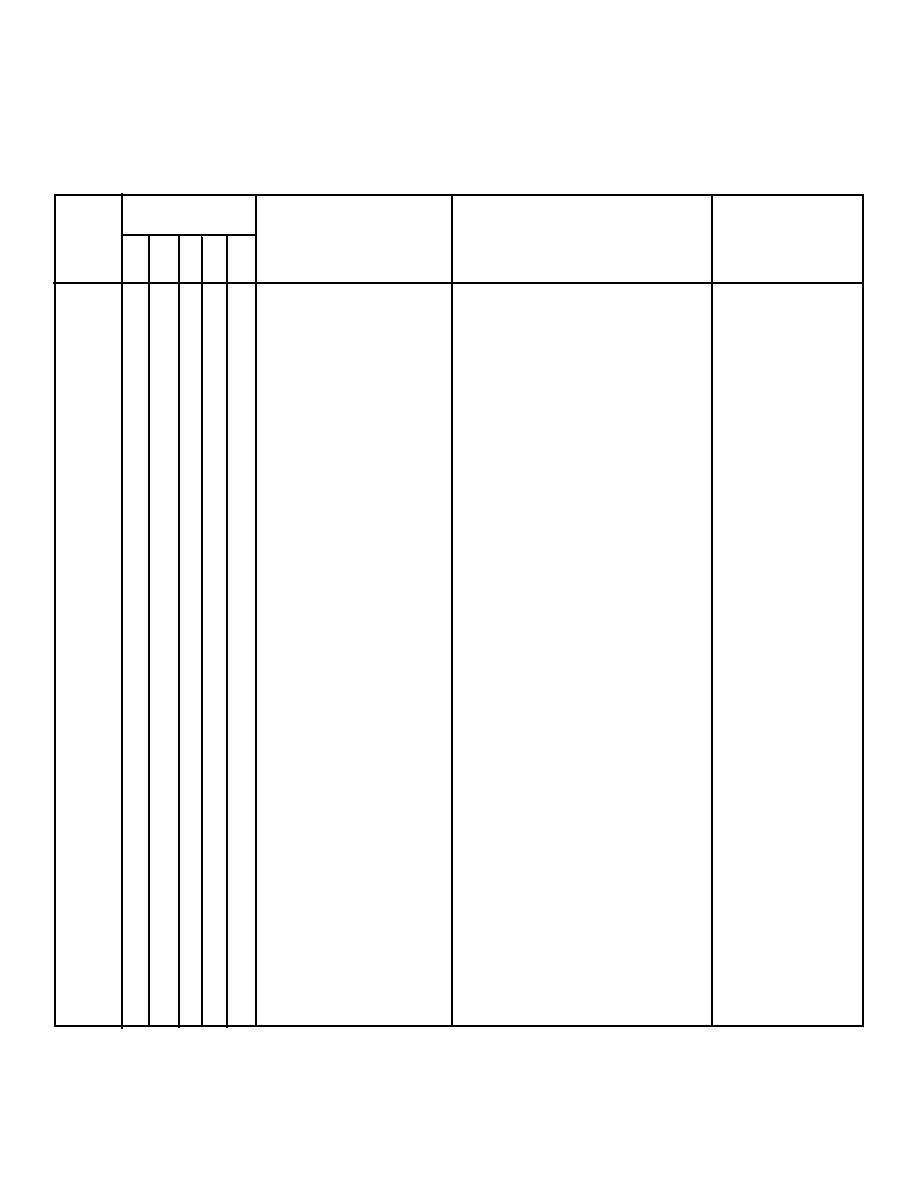

Table 2-3. (ARMY) Operator/Crew Preventive Maintenance Checks and Services (Unit) - Continued

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

Item to be

Procedures

Equipment is

ITEM

Inspected

Check for and have repaired

not ready/

NO.

B

D

AWM

or adjusted as necessary.

available if:

12

Listen for unusual noises during

con't

operation. Notify organizational

maintenance to replace

malfunctioning pump. For sight

glass location and oil filling

instruction, see lubrication order

LO 10-4610-240-12/LI

08580C-12/TO 40W4-13-31.

13

Chemical feed

Check for loose mounting nuts

Motor will not

pump motor.

and bolts. Look for loose wires at

operate.

conduit box. Listen for unusual

noises during operation. Notify

direct support maintenance to

replace malfunctioning motor.

14

Chemical feed

Inspect for broken or missing

Blocked valves or

Run/Prime valves

pipe to hose adapters. Check for

excessive leakage.

free operation of valve handles.

Check for chemical corrosion.

15

Color comparator

Inspect the color comparator kit

kit, TDS meter

and TDS meter. Look for:

Poor condition

Dirty sample cells

Dirty color discs

Cracked or dirty frosted

glass

Clean as necessary.

16

Regulate product

Inspect for loose pipe

Valves will not

flow valve and

connections. Inspect valves to

operate or excessive

backwash valve

see if they operate freely and do

leakage.

not leak. Tighten loose

connections. Notify unit

maintenance if valves bind or

leak.

2-23