TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

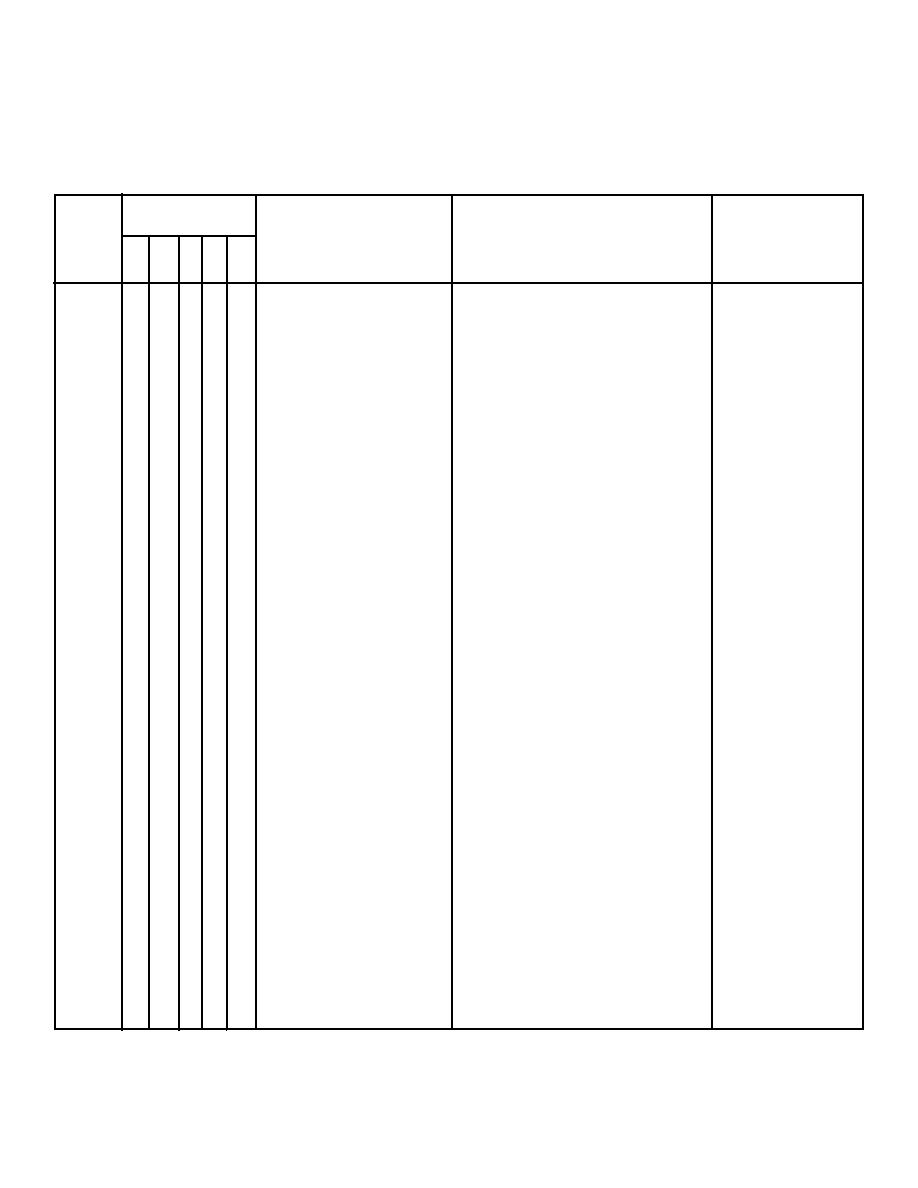

Table 2-3. (ARMY) Operator/Crew Preventive Maintenance Checks and Services (Unit) - Continued

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

Item to be

Procedures

Equipment is

ITEM

Inspected

Check for and have repaired

not ready/

NO.

B

D

AWM

or adjusted as necessary.

available if:

5

Multimedia filter

Inspect for leaky gaskets, and

Raw water will not

loose mountings. Notify

flow through filter.

organizational maintenance if

Filter cannot be

you find trouble. Check

backwashed. Gage

multimedia gage readings.

reading exceeds

Should read within 5 psid of

either 5 psid of initial

initial log reading, and in no

log reading or 10

case should exceed 10 psid.

psid.

6

Cartridge filter

Check for leaks. Check

Raw water will not

cartridge filter gage readings.

flow through filter.

Should be 1-20 psid.

Gage reads over 20

psid.

7

Gages and flow

Inspect for broken glass. Look

Gages or flow

indicators

for loose mountings and tube

indicators are

connections.

inoperative.

8

Frames:

Inspect for damaged or bent

ROWPU

frames, loose mounting bolts,

Backwash pump,

and missing or broken tiedowns

Distribution

and frame pins. Inspect

pump,

crossmembers and beams for

Raw water

cracks and breaks. Tighten

pumps

loose mounting bolts. Report

breaks, misfits, cracks,

damaged framework, or missing

hardware to organizational

maintenance.

9

Canvas items:

Inspect for rips, tears, or other

frame cover,

damage. Report damaged items

pump covers,

to organizational maintenance.

holddown straps

2-21