TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

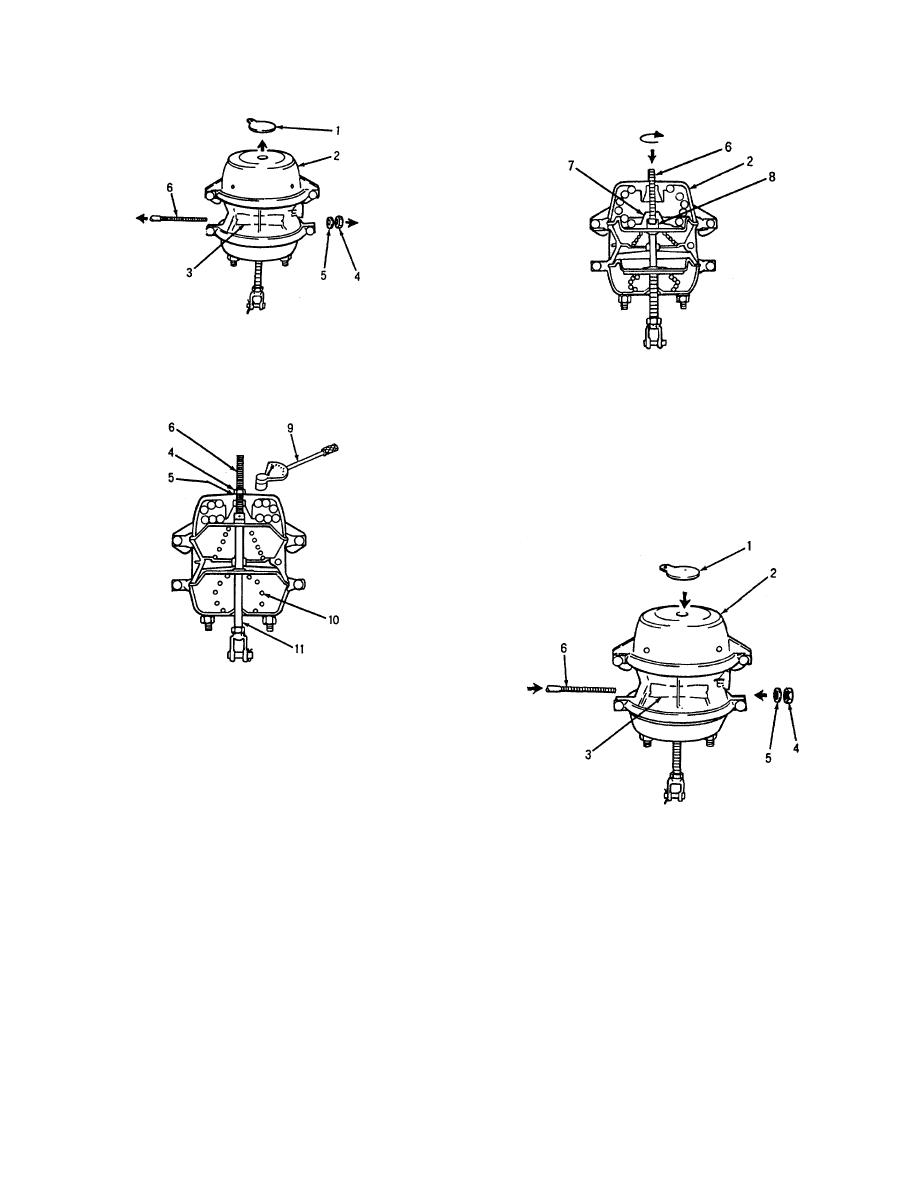

1. REMOVE DUST CAP (1) FROM TOP OF SPRING

CHAMBER (2).

REMOVE RELEASE STUD

ASSEMBLY FROM SIDE SLEEVE (3) BY

REMOVING RELEASE STUD NUT (4) AND

2. INSERT RELEASE STUD (6) THROUGH

WASHER (5) FROM RELEASE STUD (6) AND

OPENING (WHEN DUST CAP REMOVED) OF

SLIDING RELEASE STUD OUT OF SLEEVE.

SPRING CHAMBER (2) AND INTO THE

PRESSURE PLATE (7). TURN RELEASE STUD

(6) 1/2 TURN CLOCKWISE INTO PRESSURE

PLATE (7) TO SECURE CROSSPIN (8) IN

CROSSPIN AREA OF PRESSURE PLATE (7).

THEN LOCK PRESSURE STUD INTO MANUAL

RELEASE POSITION.

3. PLACE PREVIOUSLY REMOVED RELEASE

STUD WASHER (5) AND NUT (4) ON RELEASE

STUD (6) AND HAND TIGHTEN THE NUT ONTO

RELEASE STUD.

CAUTION

DO NOT APPLY TORQUE GREATER

THAN 35 FT-LBS.

(6.9M-KG) TO

RELEASE STUD ASSEMBLY.

4. AFTER OPERATIONAL AIR PRESSURE BUILDS

UP IN BRAKE CHAMBER AIR RESERVOIR,

USE TORQUE WRENCH (9) TO TURN

.REMOVE RELEASE STUD ASSEMBLY FROM

RELEASE STUD NUT (4) CLOCKWISE

SPRING CHAMBER (2) AND STOW IN SIDE

UNTIL COMPRESSION SPRING (10) IS

SLEEVE (3), BY INSERTING RELEASE STUD (8)

FULLY

CAGED.

WHILE

THROUGH SIDE SLEEVE (3) AND INSTALL

COMPRESSING

SPRING

(10),

WASHER (5) AND NUT (4). REPLACE DUST

OBSERVE THAT SERVICE PUSH ROD

CAP (1) ON SPRING CHAMBER (2).

(11) IS RETRACTING AS RELEASE

STUD NUT (5) IS BEING TIGHTENED.

WHEN COMPRESSION SPRING (10) IS

FULLY CAGED, SPRING BRAKE IS

MECHANICALLY RELEASED.

FIGURE 2-77. RESETTING LOCKED) SPRING BRAKE (ARMY)

2-92