TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

Table 3-2. Troubleshooting (ROWPU) (continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

16.

PRODUCT WATER TOTAL DISSOLVED SOLIDS (TDS) LEVEL IS ABOVE 1500 PPM.

Step 1.

Check product water from each pressure vessel as follows:

a. Start up ROWPU as normal

b. Adjust R.O. PRESSURE to 960 psig. for sea water feed or 500 psig for fresh/brackish water

feed. Collect a sample of product water in a clean container and measure TI)S with portable

TDS meter (paragraph 2-15). Record value.

c. Using sample valves, collect sample product water from each vessel.

d. Using clean containers, collect a sample of product water from each end of R.O. Vessel 1. Be

sure to rinse each container twice with sample water before collecting sample. Mark container

appropriately as front or rear.

e. Measure TDS of each product water sample using the TDS meter (paragraph 2-15).

f.

Based on the TDS measurements of the collected samples, one of the following four conditions

can exist:

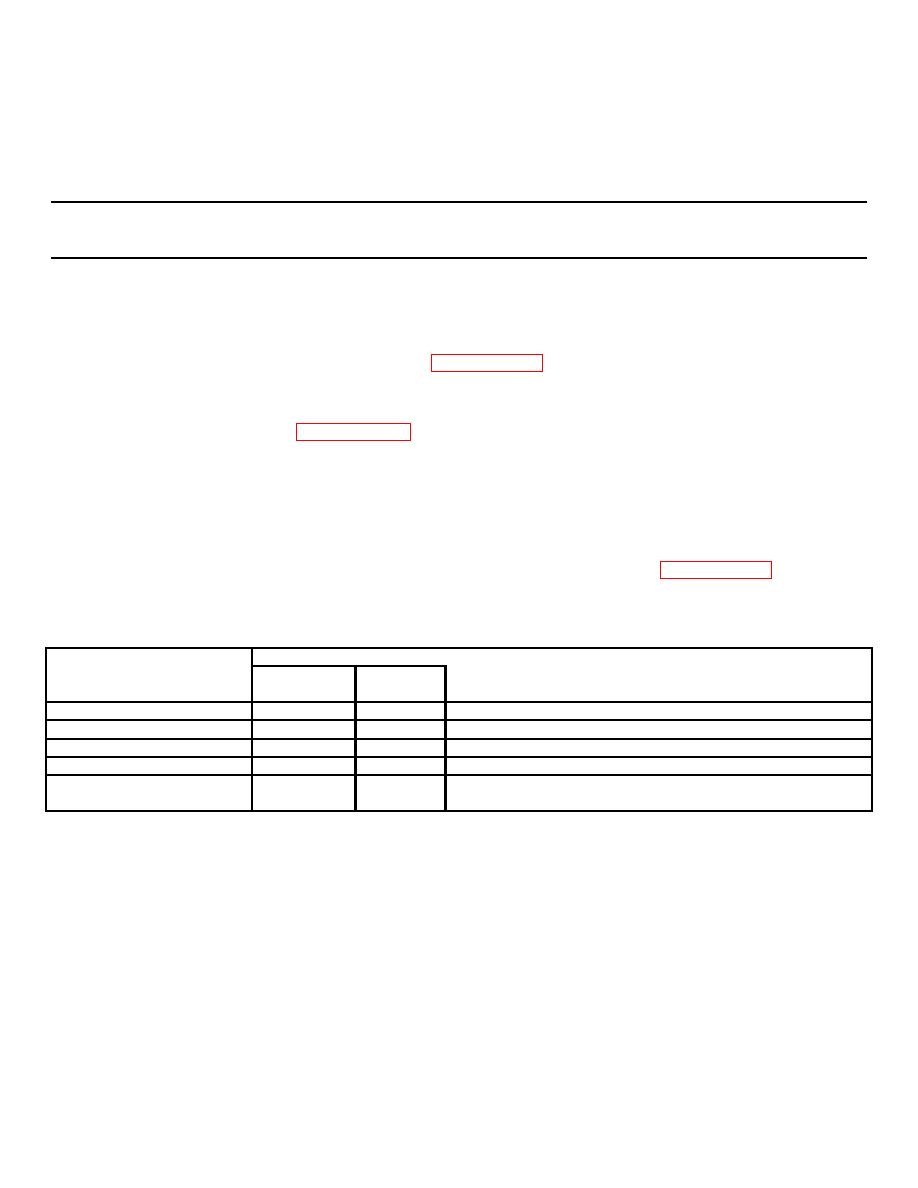

MEASURED TDS

FRONT

REAR

CONDITION

SAMPLE

SAMPLE

CAUSE

1

NORMAL

NORMAL

Vessel operation OK

2

HIGH

NORMAL

Leak at front end-connector O-rings*

3

NORMAL

HIGH

Leak at rear end-connector O-rings*

4

HIGH

HIGH

Leak at front and rear end-connector O-rings and/or

R.O. element interconnector O-rings*

*Condition could also be caused by defective R.O. element.

Condition 1: Repeat steps c through h for all remaining vessels to determine the correct source(s) of high TDS.

3-14