ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0016 00

OPERATOR INSTRUCTIONS

MAINTAINING NORMAL OPERATION UNDER USUAL CONDITIONS

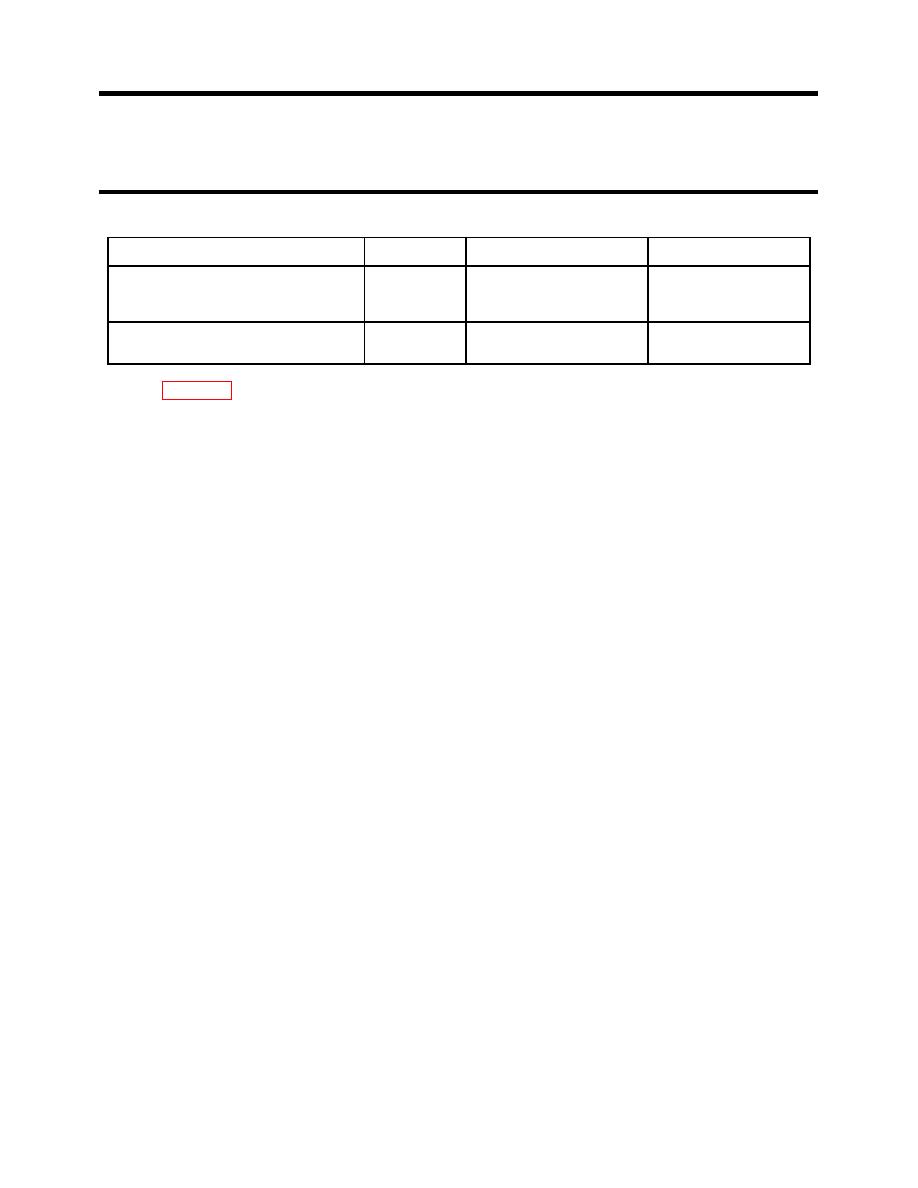

Table 4. RO Cleaning Schedule.

RO % Clean

% Salt

Problem

Cleaning

Rejection

Indicated

Required

Less than 90% and a decrease of 10% or

Unchanged

Silt fouling, or biological film

RO Detergent Cleaning

more since beginning the mission or last

growth from inadequate

(High pH cleaner AC-310

cleaning

preservation

Detergent)

Less than 90% and a decrease of 10% or

Decreased

Scale

RO Acid Cleaning (Low pH

more since beginning the mission or last

cleaner AC-210 Citric Acid)

cleaning

Refer to WP 0020, Cleaning and Preservation Introduction, for cleaning procedures.

MF PRESSURE INTEGRITY AND SONIC TESTS

MF Pressure Integrity Test:

This is an automated self-test. From STANDBY with the MF full of water, the filtrate is drained and

purged with air. An air pressure of approximately 15 psig is then applied to the MF modules and shut off.

Broken membrane fibers will leak air out the open ends of the fibers into the feed water (shell) side of the

modules. As the air leaks out, the air pressure will decrease. The PLC notes the air pressure after 2

minutes and again after 2 additional minutes. The PLC compares the pressures to determine if the

leakage is excessive. If MF Filtrate Pressure Transmitter PT-102 is not functioning properly (TMP cannot

be zeroed), the automatic test will give a fail indication. In this event, the MF Pressure Integrity can be

checked manually using readings from MF Filtrate Pressure Gauge PI-201.

NOTE

New MF membranes will not be fully wetted until they have been operated for 50 - 200

hours. Without full wetting, they will not pass the integrity test. This does not indicate a

problem.

Perform the automatic MF Pressure Integrity Test as follows:

1. Shutdown the TWPS to STANDBY.

2. Set the MF Test Switch to PRESSURE.

a. The test automatically sequences.

b. The MF Integrity Test indicator light is on during the test.

3. At the end of the test the same indicator light indicates pass/fail.

a. Light off Pass.

b. Light flashing Fail.

4. If the test indicates failure, continue with the Sonic Test.

Perform the MF Pressure Integrity Test manually using MF Filtrate Pressure Gauge PI-201 as follows:

1. Shutdown the TWPS to STANDBY.

2. Set the MF Test Switch to PRESSURE.

3. Wait 2 minutes, then record the reading from MF Filtrate Pressure Gauge PI-201. A reading of

less than 10 psig indicates failure.

4. If the reading is 10 psig or higher, wait an additional 2 minutes, then record the reading again.

5. Subtract the second reading from the first reading. A result greater than 6 psig indicates failure.

0016 00-12