ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0016 00

OPERATOR INSTRUCTIONS

MAINTAINING NORMAL OPERATION UNDER USUAL CONDITIONS

d. If the TDS reference (far left of display) is not set to "NaCl", press "TDS" and then press

and hold CAL until the "SEL". Is displayed.

e. Use the up/down arrows to change the TDS reference to "NaCl"

f. Press CAL again. Press TDS and record the reading.

b. Press TDS to measure the Total Dissolved Solids. The reading will be in Parts Per

Million (PPM), which is equivalent to milligram per liter (mg/l).

c. Record the reading in the RO Element Performance Log (WP 0082, TDS column).

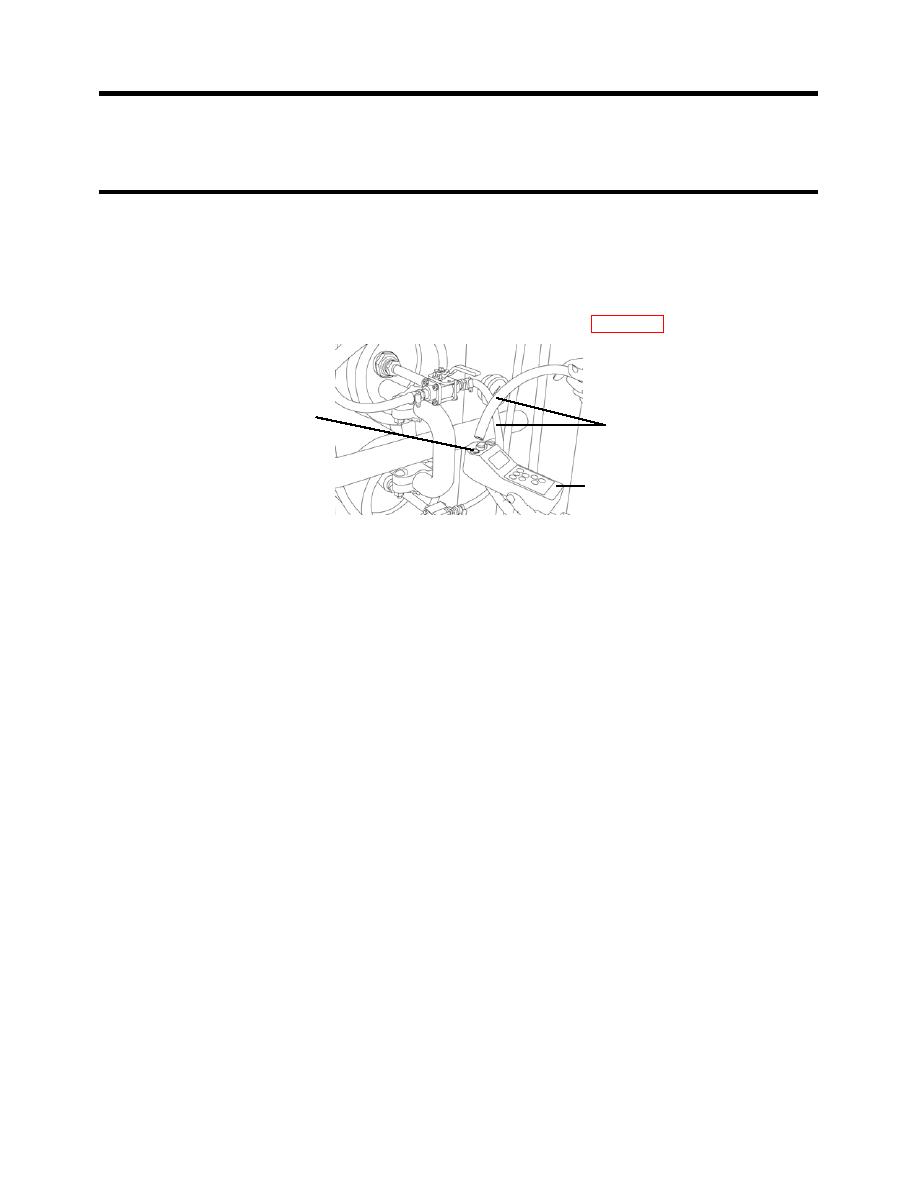

TDS METER CUP

SAMPLE TUBE

TDS METER

Figure 9. RO Element Product Water Conductivity Test Setup.

6. Repeat the product flow and conductivity tests for each of the RO elements.

MANUAL FLOW CONTROL

Manual flow control is used as a backup control procedure if the automatic control fails to properly fill the

RO Feed Tank or if the automatic control overflows the tank.

1. At the Feed Flow Control Panel, turn the Feed Control Selector handle from the Auto position to

the Manual position.

2. Use the Manual Feed Control to adjust the MF Feed Flow. Turning the control dial clockwise will

decrease the flow. Turning the control counter-clockwise will increase the flow.

3. If the RO Feed Tank Level display is not working, open the RO Feed Tank cover to observe the

level.

4. While operating, set the flow to approximately 65 gpm until the level is within 4 inches of the top.

The tank must be refilled before the backwash begins. Then reduce the flow to approximately 55

gpm or as needed to hold the level at or above 4 inches from the top without overflowing until the

backwash begins.

5. As soon as the backwash is complete, increase the flow to fill the tank again.

RESPONDING TO NORMAL OPERATION ALARMS

NOTE

When an alarm sounds and a red alarm light comes on, unless the unit automatically shuts

itself down, continue operation and follow the applicable instructions in Table 5.

1. When an alarm sounds, turn the Alarm Switch to SILENCE.

2. After correcting the cause of the alarm, or after shutdown to standby to correct the cause of the

alarm, turn the Alarm Switch to RESET.

3. For alarms during normal operation, refer to Table 5 to determine the corrective action to take.

4. For alarms during startup and cleaning, refer to the specific startup or cleaning procedures.

0016 00-17