ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0016 00

OPERATOR INSTRUCTIONS

MAINTAINING NORMAL OPERATION UNDER USUAL CONDITIONS

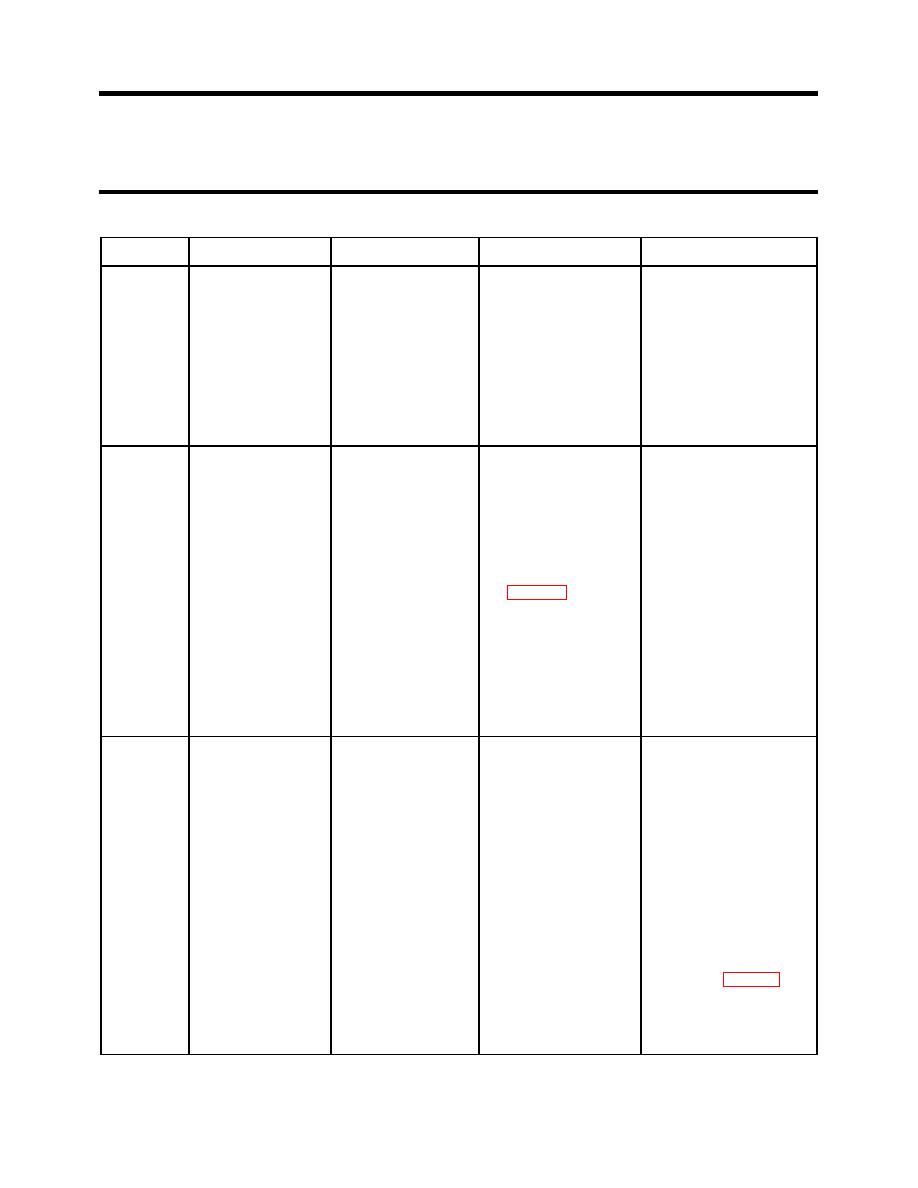

Table 5. Normal Alarms and Alarm Responses Continued.

Alarm

Immediate

Problem

Test or Inspection

Corrective Actions

Response

Clean

- Set Mode to Standby.

(1) MF Feed Strainer S-

(1) Check strainer basket.

(1) Clean.

Strainer

- Drain RO feed tank.

2 fouled.

(210 to 190

- Open the MAIN circuit

gpm

breaker at the PDP

(2) Debris in MF Feed

(2) Remove the hoses and

(2) Remove any debris

backwash

(OFF position)

Pump.

adaptor. Check for debris

found.

flow)

- Then close the MAIN

in the pump inlet or outlet.

circuit breaker (ON)

- Follow normal startup

(3) MF Feed Pump

(3) Continue operation.

procedures

worn.

Notify Unit Maintenance.

- Troubleshoot if alarm

re-occurs.

MF

- Set Mode to Standby.

(1) MF Feed tank out of

(1) Check MF Feed Tank

(1) Open flow control valve.

Backwash

- Drain RO feed tank.

water

Level. Should not be less

Flow Low

- Open the MAIN circuit

than 25% full at end of

(Backwash

breaker at the PDP

backwash.

flow less

(OFF position)

than 190

- Then close the MAIN

(2) Automatic valve

(2) Step through the BIT

(2) If a valve fails to operate

gpm)

circuit breaker (ON)

failure.

self-tests to identify if an

or cycle fully, notify Unit

- Follow normal startup

automatic valve fails to

Maintenance. Do not

procedures

cycle or fails to cycle fully

continue operation.

- Troubleshoot if alarm

(see WP 0013).

re-occurs.

(3) Flow measurement

(3) Resume operation.

(3) Continue operation.

loop failure.

Note the backwash flow. If

Notify Unit Maintenance.

it is less than 190 gpm, the

flow measurement loop

may have failed.

(4) Severely fouled

(4) See Clean Strainer (1)

(4) See Clean Strainer (1)

strainer S-2 or MF Feed

and (2)

and (2). Check MF Feed

Pump

Tank Strainer S-1 for breaks.

MF TMP

Continue operation.

(1) Pressure transmitter

(1) Compare TMP with

(1) Continue operation. Use

High

Note operating hour

PT-102 failure

Operating Data Log

pressure gages PI-101 and

reading on hour meter.

entries. If it is much higher

PI-201 to determine the TMP.

than previous entries, PT-

Notify Unit maintenance.

102 may have failed.

Compare the difference

between pressure gages

PI-101 and PI-102 with the

TMP display. If the

pressure gages show a

lower TMP, this also

confirms PT-102 failure.

(2) MF TMP Zero out of

(2) Check TMP for zero at

(2) Adjust Zero if needed.

adjustment.

next PMCS shutdown.

(3) MF fouled and ready

(3) Schedule routine

(3) Clean MF (WP 0021).

for routine cleaning.

cleaning within 40 hours.

Do not exceed maximum

pressures listed for various

temperatures in Table 6.

Clean sooner if required.

0016 00-19