ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0020 00

OPERATOR INSTRUCTIONS

CLEANING, PRESERVATION, AND CLEANING WASTE

NEUTRALIZATION AND PUMP-OUT

RO ACID CLEANING

The filtered water, or filtrate, from the MF modules is pumped under pressure through the RO vessels.

The RO element membranes reject dissolved solids (salts) in the filtrate. Antiscalant is injected into the

filtrate during normal TWPS operation to prevent salt scale from forming on the RO membranes. If the

antiscalant is not properly injected, or if the source water is well or seawater in Middle Eastern countries,

the RO membranes can gradually become clogged with salt scale. If the RO is not properly preserved,

the membranes can become clogged with a biological film. If some of the MF fibers are damaged or

broken, silt or dirt can pass through and clog the RO membranes.

When the TWPS is operated properly, scaling, biological growth, and silt accumulation in the RO element

membranes are very unlikely. Therefore, acid cleaning of the RO is seldom required. If cleaning does

become necessary, the need for RO acid cleaning is indicated by the % Clean calculation and the % Salt

Rejection display on the OCP. Table 1 identifies the % Clean and % Salt Rejection criteria that indicates

that RO acid cleaning is needed. RO % Clean and RO % Salt Rejection are described in more detail in

data indicates scaling or silt or biological fouling, an RO acid cleaning should be performed followed by an

RO detergent cleaning.

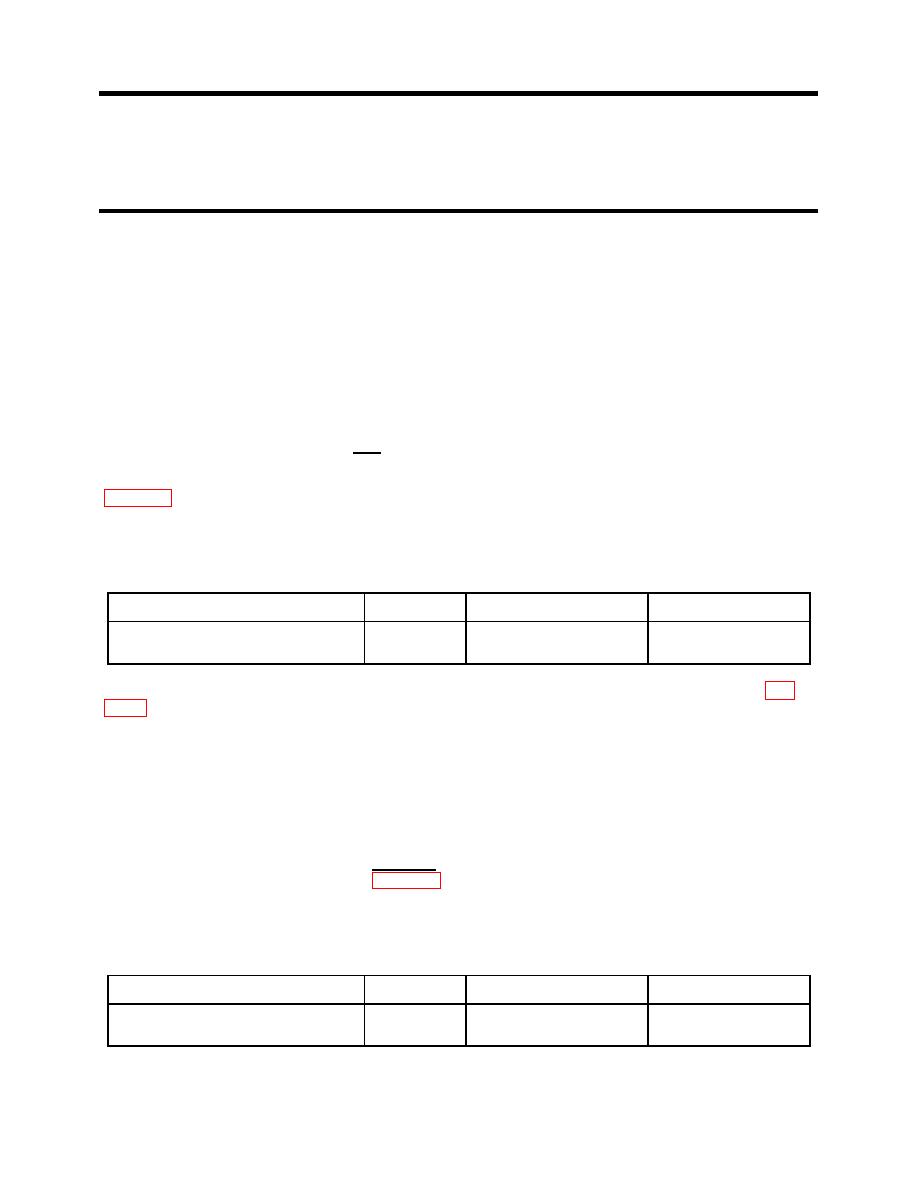

Table 1. RO Acid Cleaning Schedule.

RO % Clean

% Salt

Problem

Cleaning

Rejection

Indicated

Required

Less than 90% and a decrease of 10% or

Decreased

Scale

RO Acid Cleaning (Low pH

more since beginning the mission or last

cleaner AC-210 Citric Acid)

cleaning.

AC-210 citric acid is used for the RO acid cleaning. RO Acid Cleaning procedures are described in WP

RO DETERGENT CLEANING

Like RO Acid Cleaning, RO Detergent Cleaning is seldom required. The excellent RO feed water

provided by the MF avoids most of the RO fouling typically associated with dirt and biological material.

If cleaning does become necessary, the need for RO detergent cleaning is indicated by the % Clean

calculation and the % Salt Rejection display on the OCP. Table 2 identifies the % Clean and % Salt

Rejection criteria that indicates that RO detergent cleaning is needed. RO % Clean and RO % Salt

Rejection are described in more detail in WP 0016, Maintaining Normal Operation. If you are unsure

whether your % Clean and % Salt Rejection data indicates scaling or silt or biological fouling, an RO acid

cleaning should be performed followed by an RO detergent cleaning.

Table 2. RO Detergent Cleaning Schedule.

RO % Clean

% Salt

Problem

Cleaning

Rejection

Indicated

Required

Less than 90% and a decrease of 10% or

Unchanged

Silt or biological fouling

RO Detergent Cleaning

more since beginning the mission or last

(High pH cleaner AC-310

cleaning.

Detergent)

0020 00-2