ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0033 00

TROUBLESHOOTING PROCEDURES

OPERATOR/CREW TROUBLESHOOTING PROCEDURES

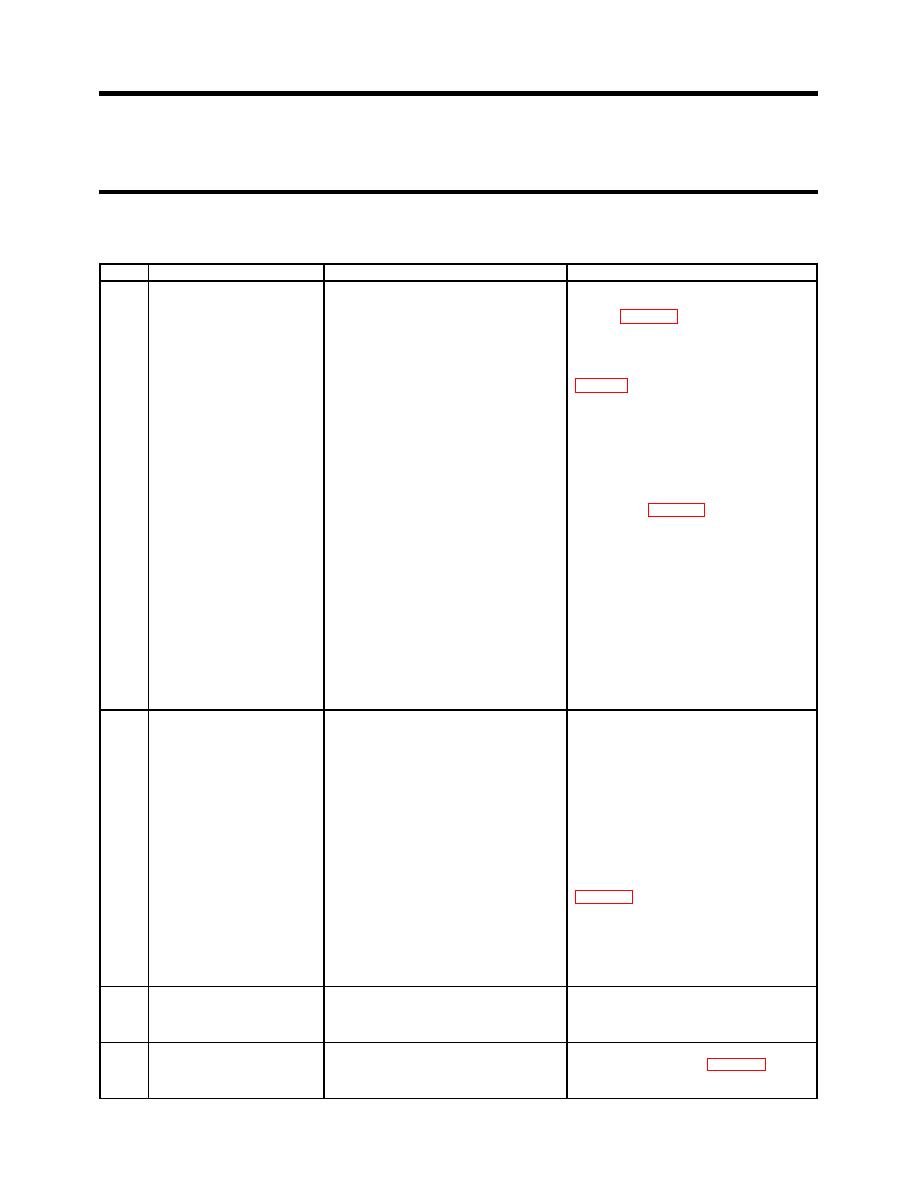

Table 10. Air Compressor Troubleshooting.

ITEM

MALFUNCTION

POSSIBLE CAUSES

CORRECTIVE ACTION

1

Compressor does not start

CB133 circuit breaker tripped.

Open PDP and check CB133 circuit

with switch in Auto and no

breaker (WP 0011). Reset as needed. If it

pressure. Switch light is ON.

trips again, notify Unit Maintenance to

check for shorts.

Or

Thermal overload on contactor M510

Push in blue button on contactor M510

Compressor was running and

tripped.

stopped at a pressure well

Maintenance.

below 975 psig. Switch light

is ON.

Compressor high temperature switch has

Allow compressor to cool. Be sure that the

tripped.

airflow is not obstructed. Check the oil

level. After cooling, toggle RESET and

start compressor.

1) Check the oil sight glass for air.

Bleed the lubrication system as

needed (WP0042).

2) If this occurs after motor

replacement, check rotation. Notify

Unit Maintenance if not correct.

Compressor high temperature switch has

failed.

If the Reset does not clear the light after the

compressor has cooled to the touch, the

temperature switch has failed. Notify Unit

Maintenance.

Oil pump or oil pressure regulator has

failed.

If the Reset does clear the light after

cooling, Notify Unit Maintenance to check

the lubricating oil pressure and replace the

pressure regulator and oil pump if

necessary.

2

Compressor does not start

Failure of Pressure Switch PSL/PSH-901

Notify Unit Maintenance.

with switch in Auto and no

low pressure turn-on switch or PLC Slot

pressure. Switch light is

#2 Input card.

OFF.

Or

Failure of PLC Slot #4 Output card or

Notify Unit Maintenance.

failure of motor contactor M510 actuating

Compressor was running and

coil.

stopped at a pressure well

below 975 psig. Switch light

Failure of PLC Slot #2 Input card or motor

Notify Unit Maintenance.

is OFF.

contactor auxiliary relay.

At first start up, circuit breaker CB133

Set CB to On position (black handle up)

manually set to OFF position (black

handle down).

Motor contactor M510 failure corroded

Notify Unit Maintenance.

main contacts.

Electrical wiring or motor failure.

Notify Unit Maintenance.

3

Safety valves between

Stage head valves not closing properly.

Notify Unit Maintenance.

individual stages releasing

pressure.

4

No flow observed in

Air trapped in oil pump.

Bleed lubrication system (WP 0042).

pressurized oil sight glass

after oil change.

0033 00-23