ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0038 00

OPERATOR MAINTENANCE PROCEDURES

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

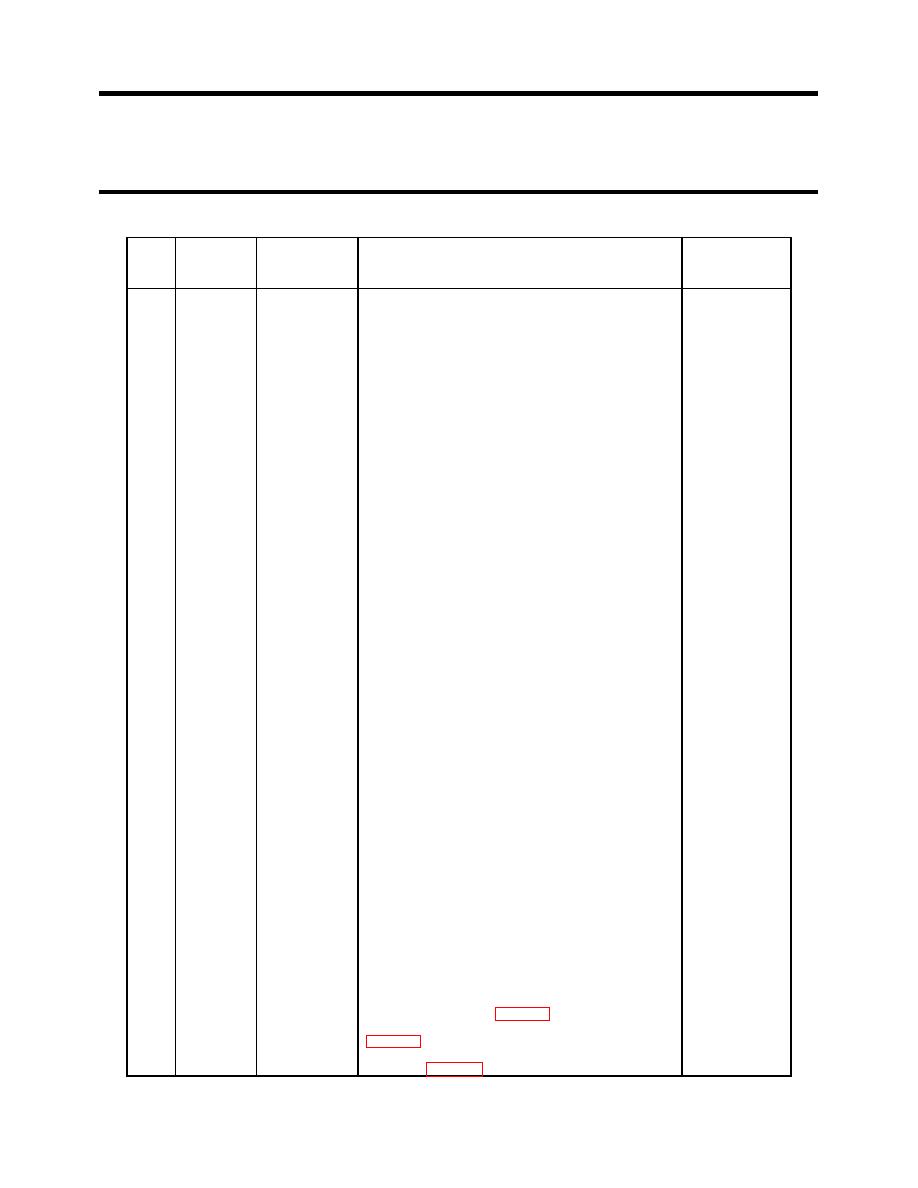

Table 1. Preventive Maintenance Checks and Services (PMCS).

ITEM

INTERVAL

ITEM TO BE

PROCEDURE

EQUIPMENT

NO.

NOT READY IF:

CHECKED OR

SERVICED

7

Before

Raw water

Inspect pump for loose mounting, damaged frame,

Pump unsafe to

pumps P1 and

cracked housing. Tighten mountings if loose. Notify Unit

operate due to

P2, MF Feed

Maintenance if damage to frame or housing found.

loose or

Pump P3, and

damaged parts.

Product Water

Distribution

Check motor/junction box connecting cable and power

Motor is unsafe

Pump P7

cable for damage. Notify Unit Maintenance to replace if

to operate

damage found.

because of

NOTE

damaged power

Make sure dust caps are installed on all unused

cable.

cables and electrical connectors.

8

Before

Cyclone

Check retainer chains for damage. Notify Unit

Both retainer

separator

Maintenance to replace if broken.

chains broken.

9

Before

Raw water and

Check for flattened hoses.

Not enough hose

distribution

assemblies

suction hoses

Check to be sure gaskets are in place. Use BII spare

available.

gaskets as needed.

10

Before

Raw water and

Check for obvious tears.

Not enough hose

distribution

assemblies

discharge

Check to be sure gaskets are in place. Use BII spare

available.

hoses

gaskets as needed.

11

Before

Raw water,

Check for broken or cracked fittings.

Damage will

distribution and

result in water

waste adaptors

streaming out

under pressure.

12

Before

Anchor Rope

Check for severe fraying.

Severely frayed

13

Before

MF Feed Tank

Check for holes and tears. Replace with spare from BII

Strainer S-1

as needed.

14

Before

MF Feed

Check to be sure that the clamps were tightened after

Strainer clamp

cleaning the strainer at the last shutdown.

and elbow

clamps

15

Before

Air compressor

Check the compressor oil level. Add oil if needed.

Insufficient oil.

assembly

Check for oil leakage as evidenced by oil on adjacent

Class III leakage.

components. Notify Unit Maintenance if leaks found. For

Class III leakage, discontinue operation of the

compressor.

Check for water in oil as evidenced by milky color on

Signs of water in

dipstick. Notify Unit Maintenance if signs of water found.

oil.

16

Before

Air compressor

Check compressor belt for -in. deflection, wear, cracks,

Belt has more

belt.

or if belt has rolled over (WP 0042). Notify Unit

than -in.

Maintenance to adjust belt tension or replace worn belt

deflection, is

worn, or has

Maintenance replace the belt when time permits if it has

cracks.

rolled over (WP 0056).

0038 00-2