ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0048 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

RAW WATER SYSTEM

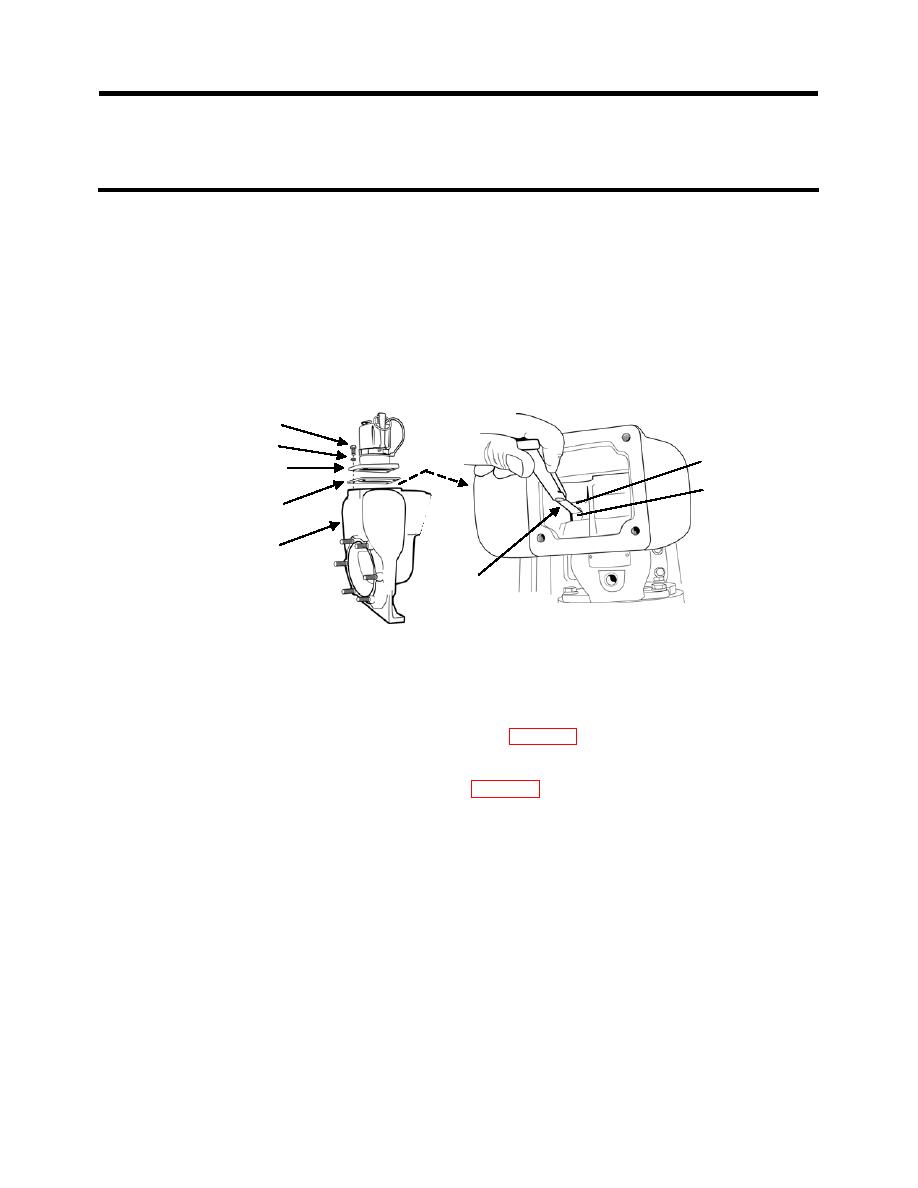

e. Insert a 0.015 inch feeler gauge between the impeller and wear plate. Move the

impeller forward or backward as needed to provide a gap of 0.015 to 0.017-inch.

f. Turn the impeller drive sleeve / impeller assembly by hand to make sure that there is a

minimum gap of 00.015-inch through the entire rotation of the impeller.

g. Make sure the coupling clamp set screw, a drive sleeve slat, and the motor shaft keyway

are aligned.

h. Tighten the coupling clamp assembly to secure the impeller drive sleeve to the motor

drive shaft. Torque the nuts to 216 in.-lbs.

i. Tighten the coupling clamp set screw into the drive shaft keyway.

CAP SCREW

LOCK WASHER

WEAR PLATE

OUTLET FLANGE

IMPELLER

OUTLET FLANGE GASKET

PUMP HOUSING

FEELER GAUGE

Figure 11. P2 Pump Impeller Clearance Adjustment.

4. Complete the installation as follows:

a. Apply sealing compound to the threads of the remaining four threaded studs extending

from the pump housing through the adapter (WP 0079, Table 1, item 25). Install the nuts

onto the studs.

b. Remove the two nuts initially installed onto opposing studs. Apply sealing compound to

the stud threads and reinstall the nuts (WP 0079, Table 1, item 25).

c. Reinstall the pump outlet flange and gasket.

5. Connect the motor cable to the proper receptacle on the junction box.

6. Place the pump back into service and inspect it for proper rotation and leaks.

Adaptor Assembly A-01 Repair / Replacement:

Parts (TM 10-610-309-24P):

Adaptor assembly A-01

Equipment Condition:

TWPS removed from service

Inspect the adaptor assembly, including valve V-101, for leaks. If a leak is found at a coupler, replace

damaged or missing gaskets as necessary. If a significant leak cannot be stopped by gasket

replacement, or if the valve does not function properly, replace the entire assembly.

0048 00-15