ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0053 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

HIGH PRESSURE PUMPS

i.

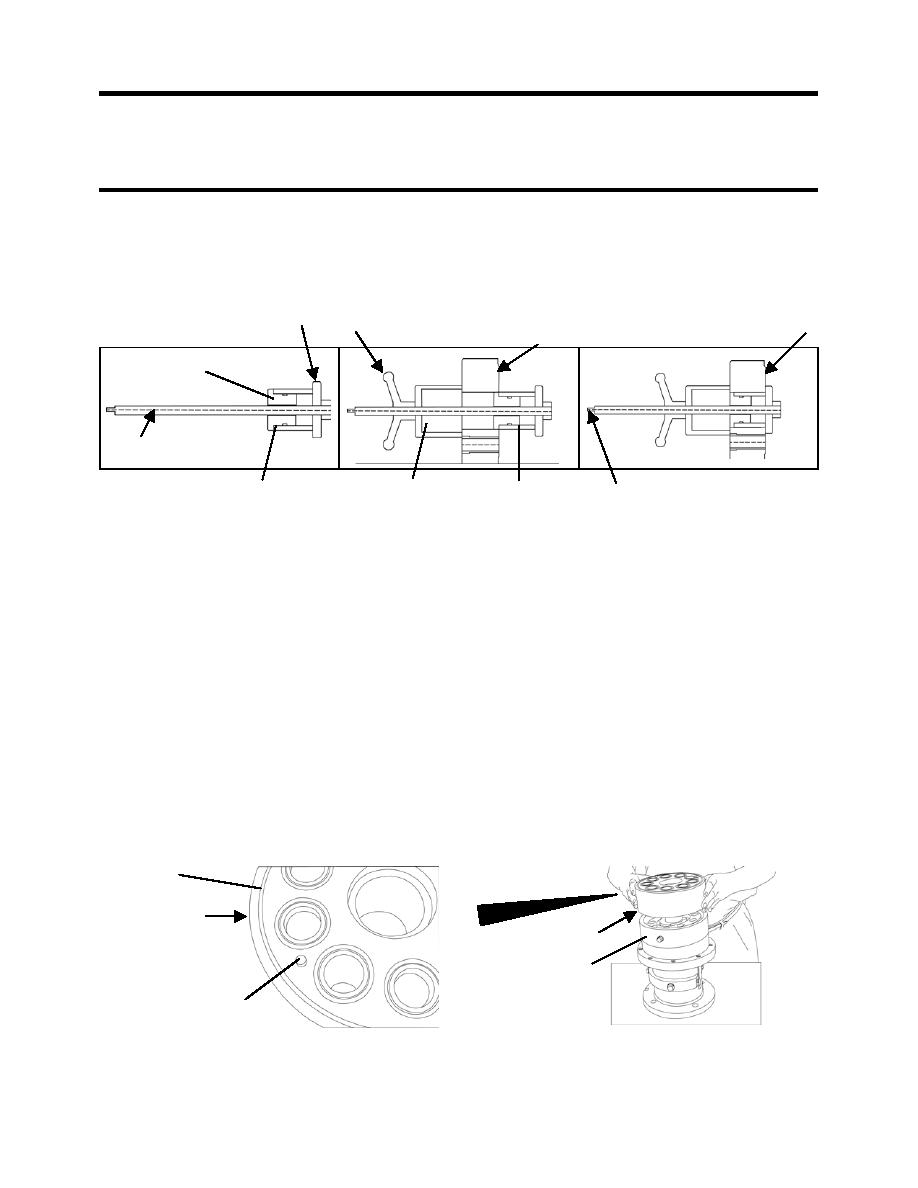

Continue to rotate the speedball handle clockwise until the reaction plate stops against

the cam side of the piston body.

j.

Remove the tool from the new bearing.

k.

Carefully clean and rinse all components with fresh water before reinstalling in the pump.

REACTION PLATE

SPEEDBALL HANDLE

PISTON BODY

CAM SIDE

PILOT PLUG

TENSION ROD

ADAPTER CAN

WRENCH FLATS

NEW BEARING

NEW BEARING

Figure 32. High Pressure Pump Body Bearing Installation.

NOTE

Make sure the key way is accessible through the pump shaft coupling cover plate.

17. Check for bad piston seals by performing the following water hold test:

a. Place the pistons into the body and push them down into their cylinders.

b. Hold the body up off the surface of the work area.

c. Pour water into the top of the cylinders.

d. If water flows through any of the cylinders and out the bottom, replace the piston in the

cylinder with the leak.

e. Repeat the test. If water still leaks through a cylinder, replace the cylinder as described

earlier in this work package.

18. Install the body as follows:

a. Make sure all cylinder liners and O-rings are installed into the body.

b. Sighting through an the open cylinder liners, make sure the liners are aligned directly

above the piston cluster cups.

c. Place the body onto the spacer.

d. Install the new O-ring between the spacer and the body outer area.

O-RING

PISTON BODY

O-RING

SPACER

ALIGNMENT PIN

Figure 33. Piston Body Installation.

0053 00-29