ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0053 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

HIGH PRESSURE PUMPS

11. Lubricate the bearing plate bearing surface with glycerin.

12. Install the cam as follows (see Figure 27):

a. Carefully rinse the cam with fresh water.

NOTE

Do not pierce or damage the shaft seal in any way.

b. Slide the clean camshaft through the bearing plate bearing and shaft seal.

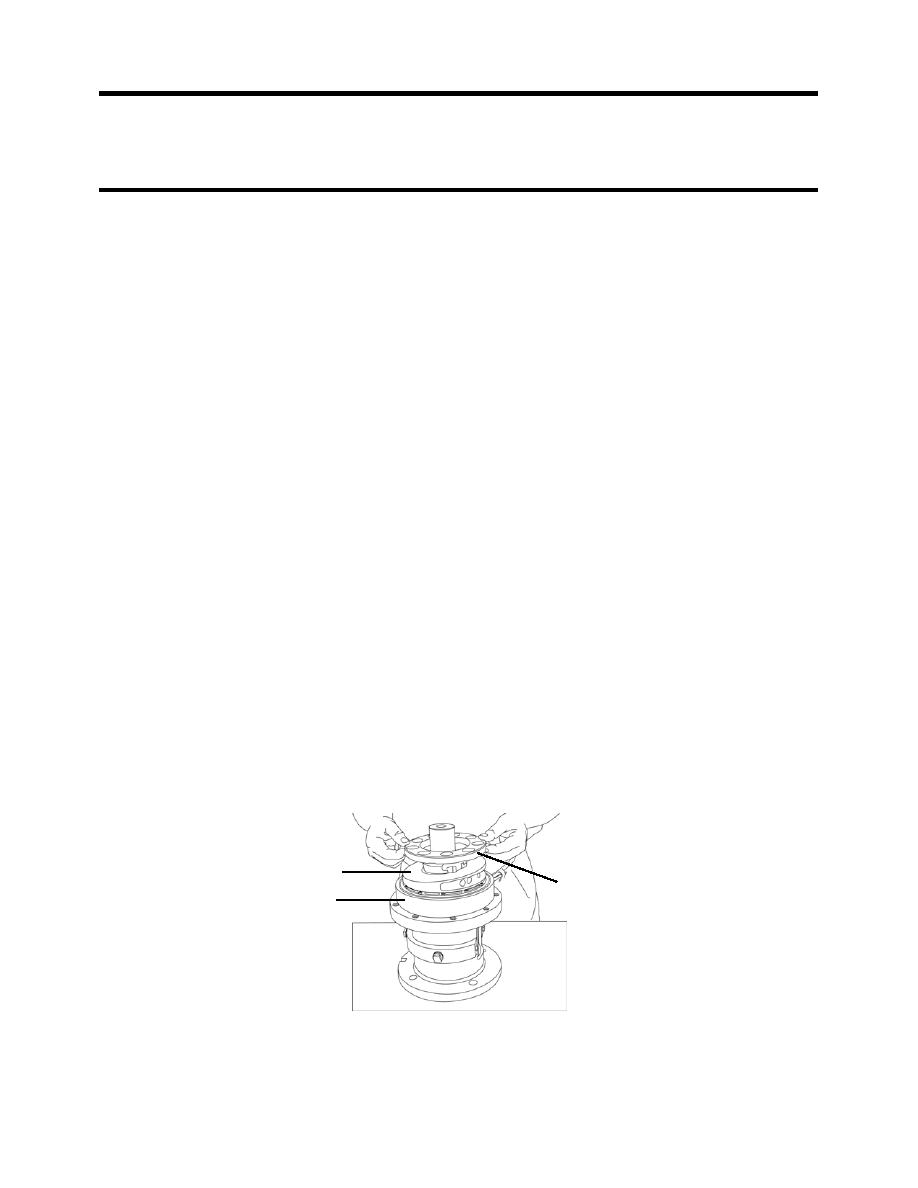

13. Inspect and (if necessary) replace the piston cluster (see Figure 28).

NOTE

The piston cluster supports the downward force of the pistons on the rotating cam

surface. During the break-in process, the piston cluster is polished-in to match the

cam surface. The piston cluster must be replaced if damage and/or wear is

discovered.

Damaged bearings may cause damage to the cam surface. Inspect and replace the

piston cluster and cam assembly as needed.

It is critical during reassembly that the pistons line up properly with the piston

cluster.

a. Inspect the piston cluster cups and flat surfaces for wear and cracking. Replace if

needed.

b. Carefully clean and rinse the piston cluster with fresh water before installing in the pump.

c. Add a drop of glycerin to each piston cluster cup and flat (bearing) surface.

NOTE

The piston cluster cups must face upwards. The position of the piston cluster

relative to the pistons is critical and should be carefully maintained during the next

two reassembly steps.

d. Place the piston cluster onto the upper cam surface.

HPP CAM

HPP PISTON CLUSTER

HPP BEARING PLATE

Figure 28. Piston Cluster Installation.

0053 00-25