ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0053 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

HIGH PRESSURE PUMPS

THRUST BEARING

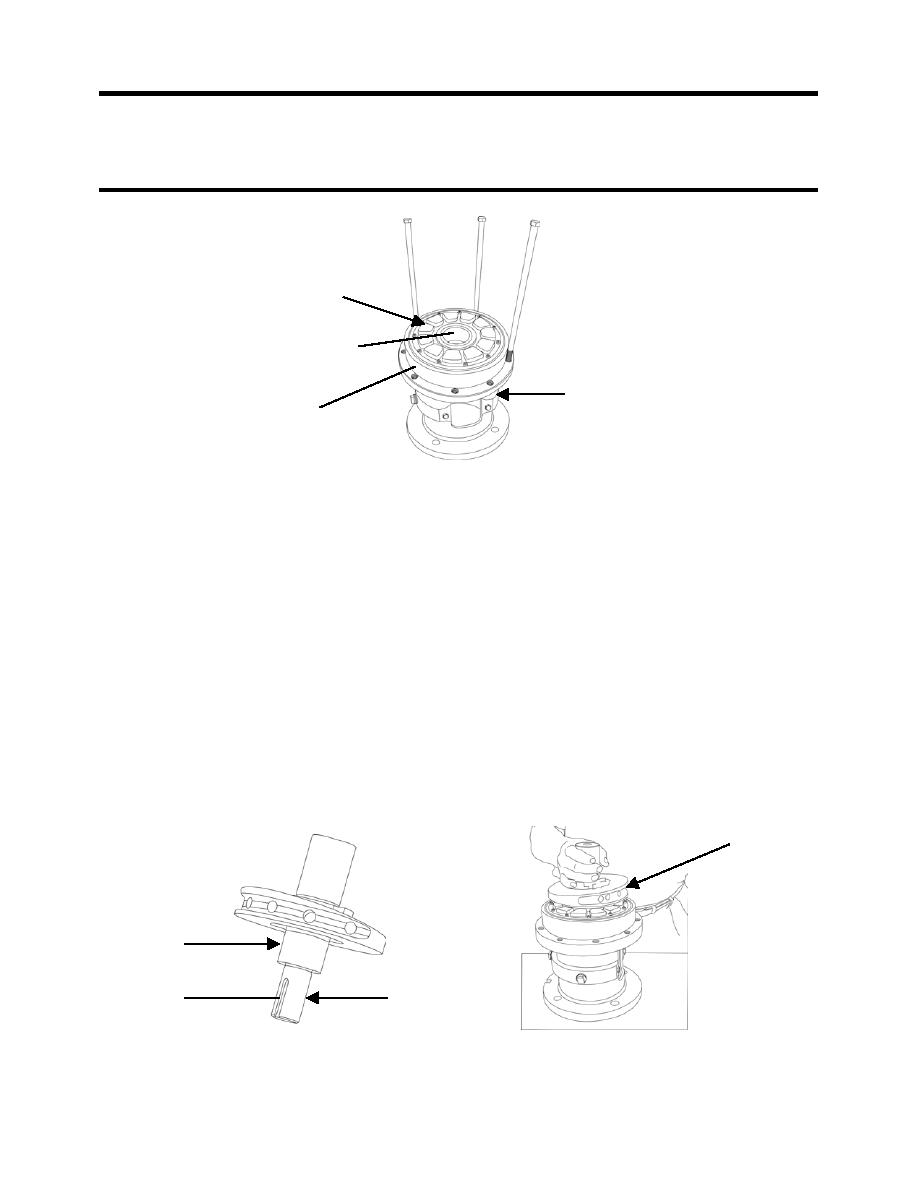

BEARING PLATE BEARING

MOUNTING FLANGE

BEARING PLATE

Figure 26. Bearing Plate and Thrust Bearing Setup.

10. Inspect and (if necessary) replace the cam as follows (see Figure 27):

NOTE

The corrosion-resistant cam upper and lower surfaces and shaft run against

bearings lubricated by the pumped fluid and are highly polished. For the pump to

operate properly, the cam upper and lower faces and shaft surfaces must be free

from scratches, nicks, or dents. Use caution when handling the cam so as not to

scratch or damage any of the bearing surfaces. Some light scoring or wear on

these surfaces is acceptable.

a. Inspect for scoring or corrosion on both the upper angled and lower flat cam surfaces and

on the shafts. Replace as needed.

b. Check the journal bearing surfaces on both ends of the cam. Replace the cam if the

surfaces have been scored or corroded.

c. Clean and rinse the cam thoroughly with fresh water before reinstalling.

d. Inspect the keyway and remove any dirt, sharp edges, or nicks that could damage the

shaft seal at installation.

HPP CAM

CAM

KEYWAY

SEAL SURFACE

Figure 27. HPP Cam Inspection and Installation.

0053 00-24