TM 10-4610-310-14

0002 00

ADDITIONAL EQUIPMENT continued

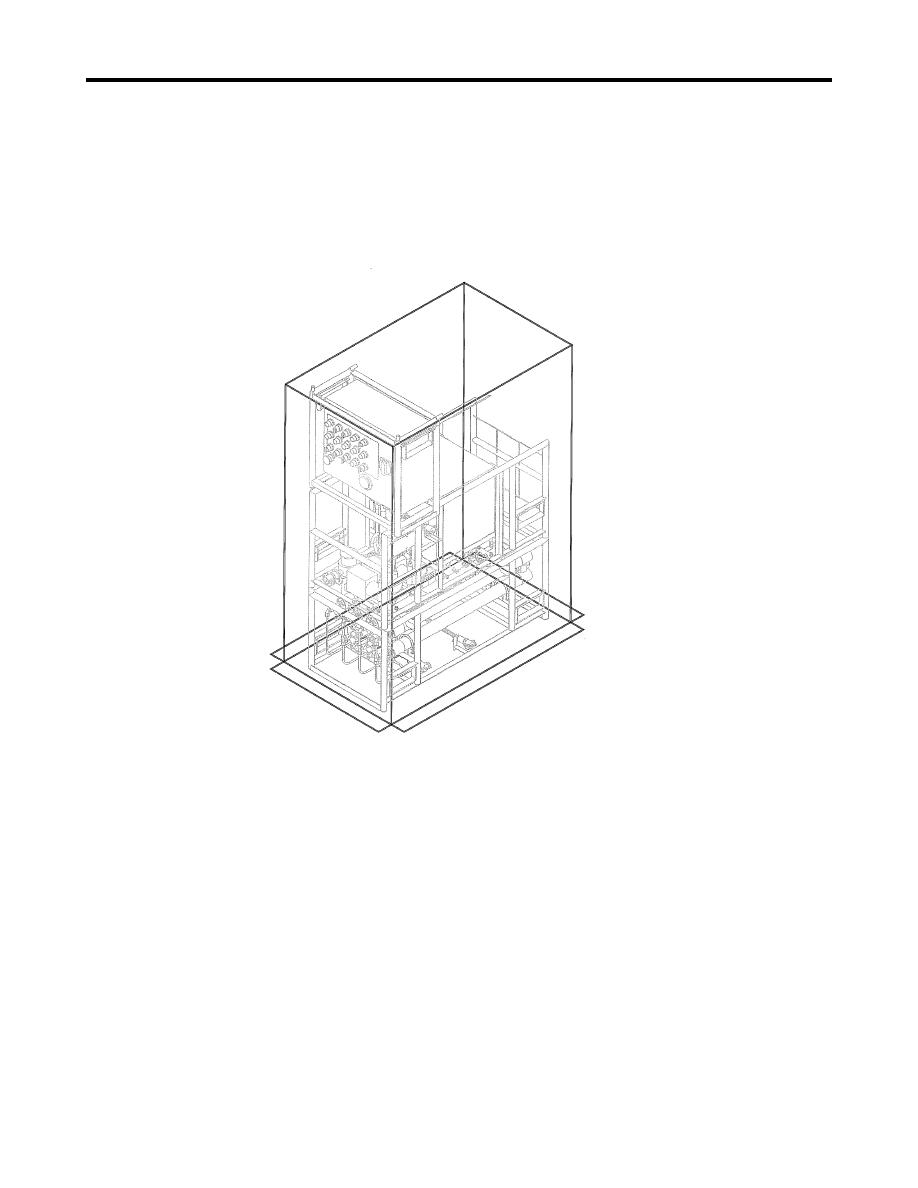

Contamination Avoidance Covers

The fabric CACs are placed on the modules to prevent NBC contamination of equipment and eliminate airborne

contaminates. There are four covers, one for the control module/RO element module/chemical injection/cleaning

module, one for the high-pressure pump module, one for the UF module, and one for the service pump skids.

After decontamination procedures of the LWP, the CACs are either decontaminated or destroyed. See Figure

19.

Figure 19. Contamination Avoidance Cover (Control Module/Chemical Module/RO Module).

Collapsible Fabric Tanks

The settling collapsible fabric tank has a circular zippered top supported by a foam collar. The settling tank is

used for the raw water source and allows suspended solids to settle to the bottom of the tank. See Figure 20.

The raw water spool piece and priming pump setup are connected to the settling tank filler connection. See

Figure 21.

The product collapsible fabric tank has a straight zippered cover to prevent intrusion of airborne contaminations

into the potable water. The product tank is used to hold the potable water produced by the LWP for distribution.

See Figure 22.

The inlet (filler) and outlet (discharge) fittings are equipped with quick disconnects, ball valve, and piping/hose.

The inlet fitting has a dust plug and the outlet fitting has a dust cap. See Figure 23 and Figure 24.

Each tank holds 1000 gallons (3800 liters) of water. The tank can be folded and handled by two personnel. The

ground cover is used as a cover for the folded tank.

The tanks are connected to the LWP, modules, and source water through a hose/piping configuration. See

Figure 1.