TM 10-4610-310-14

UNIT MAINTENANCE

LIGHTWEIGHT WATER PURIFIER

TROUBLESHOOTING PROCEDURES

CONTROL MODULE

SWITCHES

General

The table lists the common malfunctions that you may find during the operation or maintenance of the switches

on the control module used in Lightweight Water Purifier (LWP). The back panel may need to be removed to

access the switches and associating wires. You should perform the tests/inspections and corrective actions in

the order listed.

This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective actions. If a

malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

WARNING

When checking for voltage on an energized component, extreme care must be taken. Only qualified and

authorized electrician should maintain, troubleshoot, and operate energized equipment. Injury or death to

personnel may result.

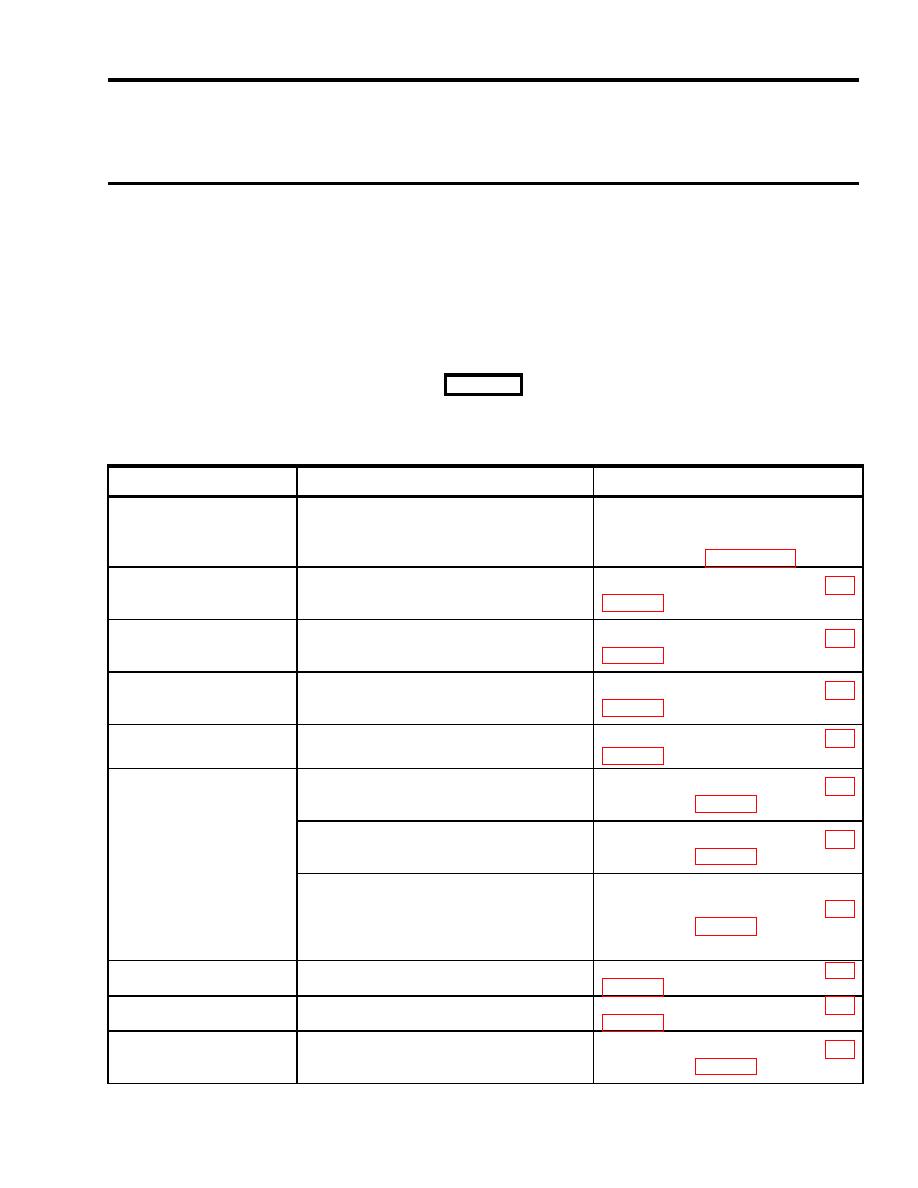

MALFUNCTION

TEST / INSPECTION

CORRECTIVE ACTION

If not present inspect wire 2 for loose

Test for power supply; ensure 120 VAC is

connection, breaks and continuity.

1. Any malfunctioning

present across wire 2 at the particular

Troubleshoot control module power

switches

switch and ground.

supply (WP 0030 00)

2. Mode selector switch

Place the switch to BACKWASH. Test for

If not present; replace the switch. WP

(backwash mode

120 VAC across wire 8 at the switch and

malfunction)

ground.

3. Mode selector switch

Place the switch to FAST FLUSH. Test for

If not present; replace the switch. WP

(fast flush mode

120 VAC across wire 9 at the switch and

malfunction)

ground.

4. Mode selector switch

Place the switch to MAINTENANCE. Test

If not present; replace the switch. WP

(maintenance mode

for 120 VAC across wire 10 at the switch

malfunction)

and ground.

5. Raw water pump

Place the switch to ON. Test for 120 VAC

If not present; replace the switch. WP

switch

across wire 49 at the switch and ground.

Place the switch to HAND. Test for 120

If not present; replace the switch. WP

VAC across wire 46 and 3 and also

across wire 48 and 3 at the switch.

Place the switch to AUTO. Place the raw

If not present; replace the switch. WP

water pump switch to ON. Test for 120

6. Chemical pump switch

VAC across wire 48 and 3 at the switch.

Place the switch to AUTO. Ensure there is

enough water in the filtrate tank for low-

If not present; replace the switch. WP

level switch to be engaged and input light

0 will be on at the PLC. Test for 120 VAC

across wire 46 and 3 at the switch.

Place the switch to ON. Test for 120 VAC

If not present; replace the switch. WP

7. Heater switch

across wire 11 at the switch and ground.

8. Distribution pump

Place the switch to ON. Test for 120 VAC

If not present; replace the switch. WP

switch

across wire 50 at the switch and ground.

Place the switch to HAND. Test for 120

If not present; replace the switch. WP

9. Backwash pump switch

VAC across wire 44 and ground at the

switch.

0070 00-1