TM 10-4610-310-14

UNIT MAINTENANCE

LIGHTWEIGHT WATER PURIFIER

TROUBLESHOOTING PROCEDURES

CHEMICAL INJECTION PUMP (ANTISCALANT)

Chemical Injection Pump (Antiscalant)

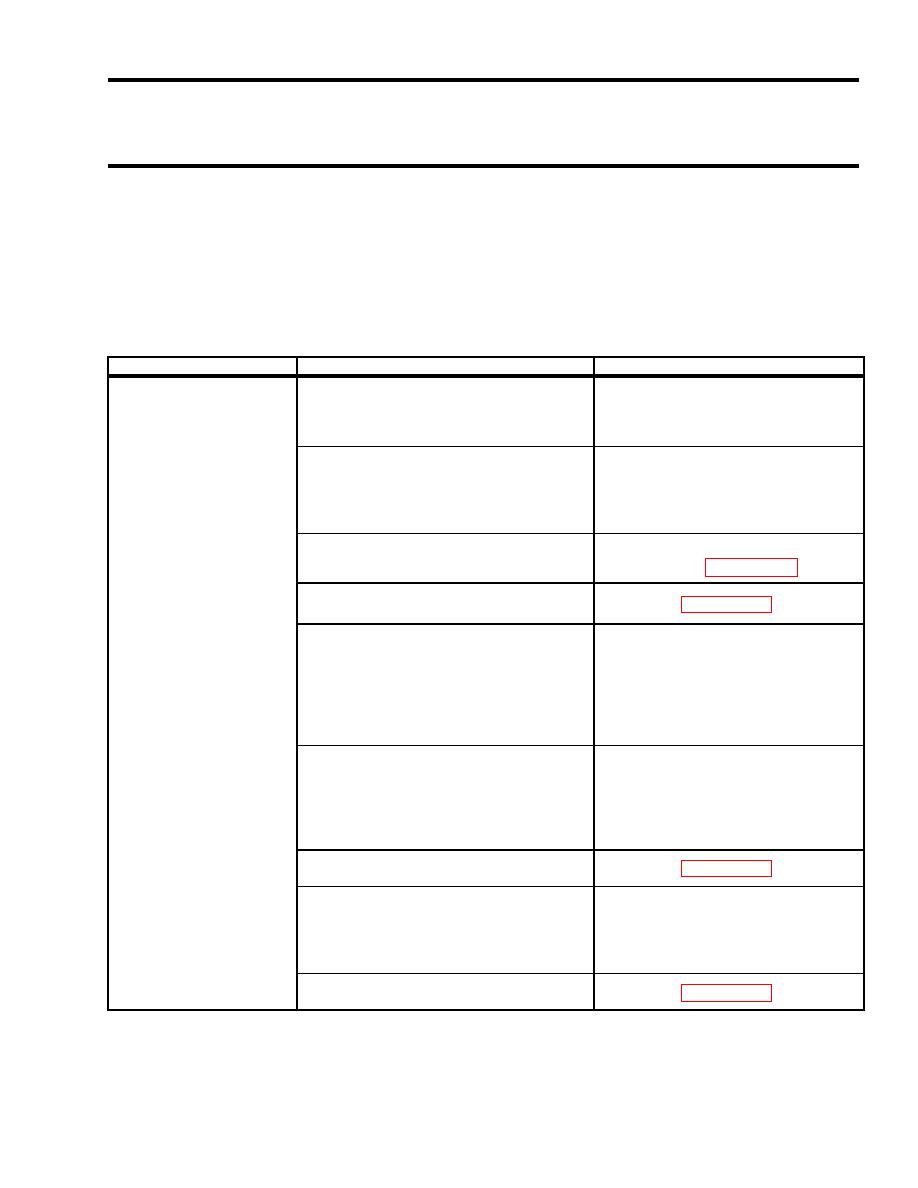

The table lists the common malfunctions that you may find during the operation or maintenance of the antiscalant

chemical injection pump assembly P5 in the chemical injection/cleaning module used in Lightweight Water

Purifier (LWP). You should perform the tests/inspections and corrective actions in the order listed.

This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective actions. If a

malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

MALFUNCTION

TEST / INSPECTION

CORRECTIVE ACTION

With power off, check wires 46, 3, and

ground for loose connections and

Tighten any loose connections.

damage from the chemical module

Repair and replace any broken wires.

junction box to the injection pump.

If present and the speed and stroke

With power on, check for voltage across

controls are not at zero but the pump

is not running, replace the pump. If

wire 46 and 3 at the chemical module

junction box. (120 VAC)

voltage is not present, proceed to the

next step.

Ensure input light 1 is energized at the

If not troubleshoot low-pressure

PLC.

switch. WP 0067 00.

Inspect chemical pump switch (SW10)

Put switch (SW10) in the auto position.

Tighten any loose connections.

Check connections of wire 38 on output

Repair and replace any broken or

10 of the PLC to the switch, and check for

1. Pump malfunctions

burnt wires. Replace if continuity

continuity of wire number 38 from the

doesn't exists in the wire.

PLC to the switch.

With power off, check connections of wire

Tighten any loose connections.

46 from the switch to the chemical

Repair and replace any broken or

module junction box, and check for

continuity of wire number 46 from the

burnt wires. Replace if continuity

doesn't exists in the wire.

switch to the chemical module junction

box.

Check surge protector (SP20) fault light

With power off, place switch (SW10) in

Tighten any loose connections.

auto and check for continuity between the

Repair and replace any broken or

terminal with wire 38 and the terminal with

burnt wires. Replace if continuity

wire 46.

doesn't exists in the wire.

Check PLC

0074 00-1