TM 3-4230-237-10

OPERATOR

M12A1 DIESEL ENGINE DRIVEN DECONTAMINATION APPARATUS

NSN 4230-01-502-7224

PUMP UNIT SUBASSEMBLY MAINTENANCE INSTRUCTIONS

DRIVE BELT TENSION INSPECTION

INITIAL SETUP:

DRIVE BELT TENSION INSPECTION

WARNING

Avoid contact with the battery's positive connection at the starter solenoid when adjusting the belt tension.

Electrical shock, fire, or damage to the equipment may result.

NOTE

Check the alternator belt after the first 15 hours of operation. Check the water pump belts and alternator

belt at 50 hours of operation.

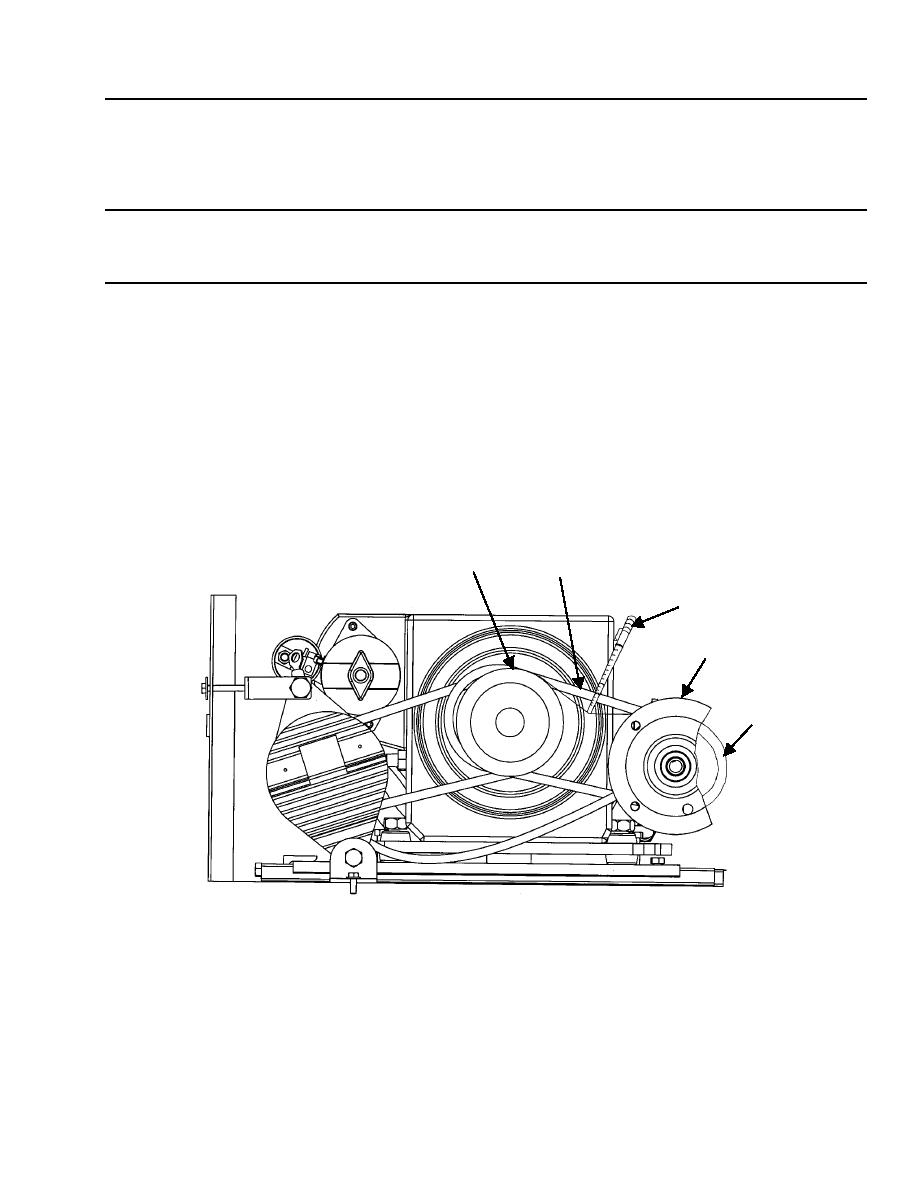

Pump Drive Belt Tension Inspection

4

3

2

1

5

1.

Check pump (1) belt tension using tensiometer (2), which can be found in the tool box.

2. Set the O-ring on the small end of tensiometer (2) at the 3/8-inch mark and set the other O-ring against the outer movable

surface of the tensiometer.

3. Place the small end of tensiometer (2) against one of the four drive belts (3) at a point halfway between drive pulley (4)

and driven pulley (5).

4.

Press down on the drive belt (3) until the O-ring at the 3/8-inch mark touches against an adjacent drive belt (3).

0023 00-1