TM 5-3800-205-10-2

TROUBLESHOOTING PROCEDURES

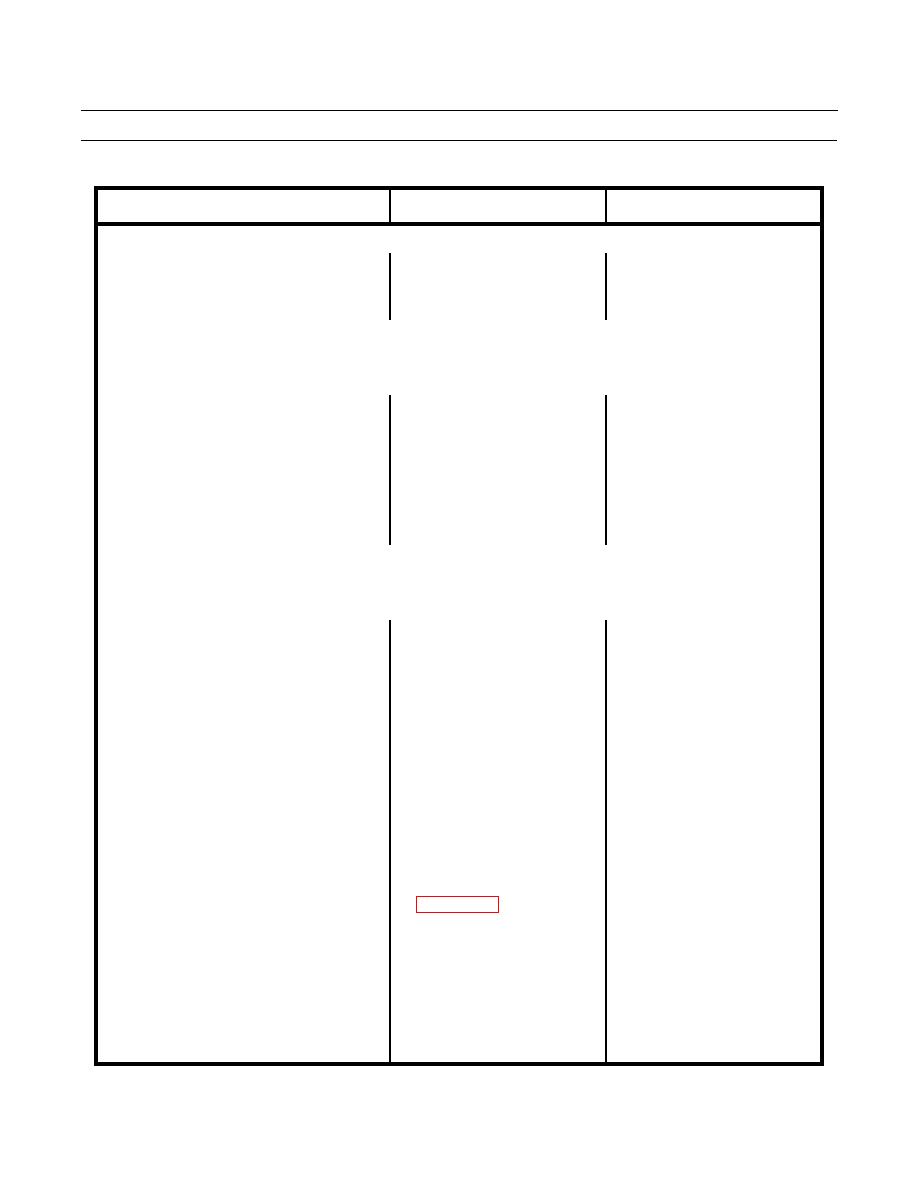

Table 1. Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

AIR SYSTEM AND BRAKES

1.

Brake Air Pressure Low Alert

Indicator, Action Light, and Action

Alarm Come On During Operation.

WARNING

When action alarm sounds, bring machine to a safe stop to prevent injury to operator and/or severe

damage to machine.

1. Ensure that air tank drain

1. Close drain valve(s) if

valve(s) are closed.

required. If problem still

exists, go to test step 2.

2. If any leaks are present, or if no

2. Check for air/hydraulic oil

leaks are found and problem

leaks at air tanks, hoses,

still exists, notify Unit

fittings, and tractor/scraper

Maintenance.

connections at hitch area.

WARNING

Park machine on level ground, stop engine, and lower tank to prevent injury to operator and/or

severe damage to machine.

1. If problem still exists, go to test

1. Place panel test switch to on

2.

Parking Brake Alert Indicator Does

step 2.

(up) and check if alert

Not Come On When Parking Brake is

indicator light comes on.

Engaged.

Release switch.

2. Check for debris/obstruction at

2. Clean debris/obstruction from

parking brake actuator.

parking brake actuator. If

problem still exists, go to test

step 3.

3. If parking brake arm moves

3. With assistance, engage then

and problem still exists, go to

release parking brake and

test step 4.

observe parking brake arm for

movement.

4. Perform parking brake test

4. If brake is engaged and

indicator light is still not on,

notify Unit Maintenance.