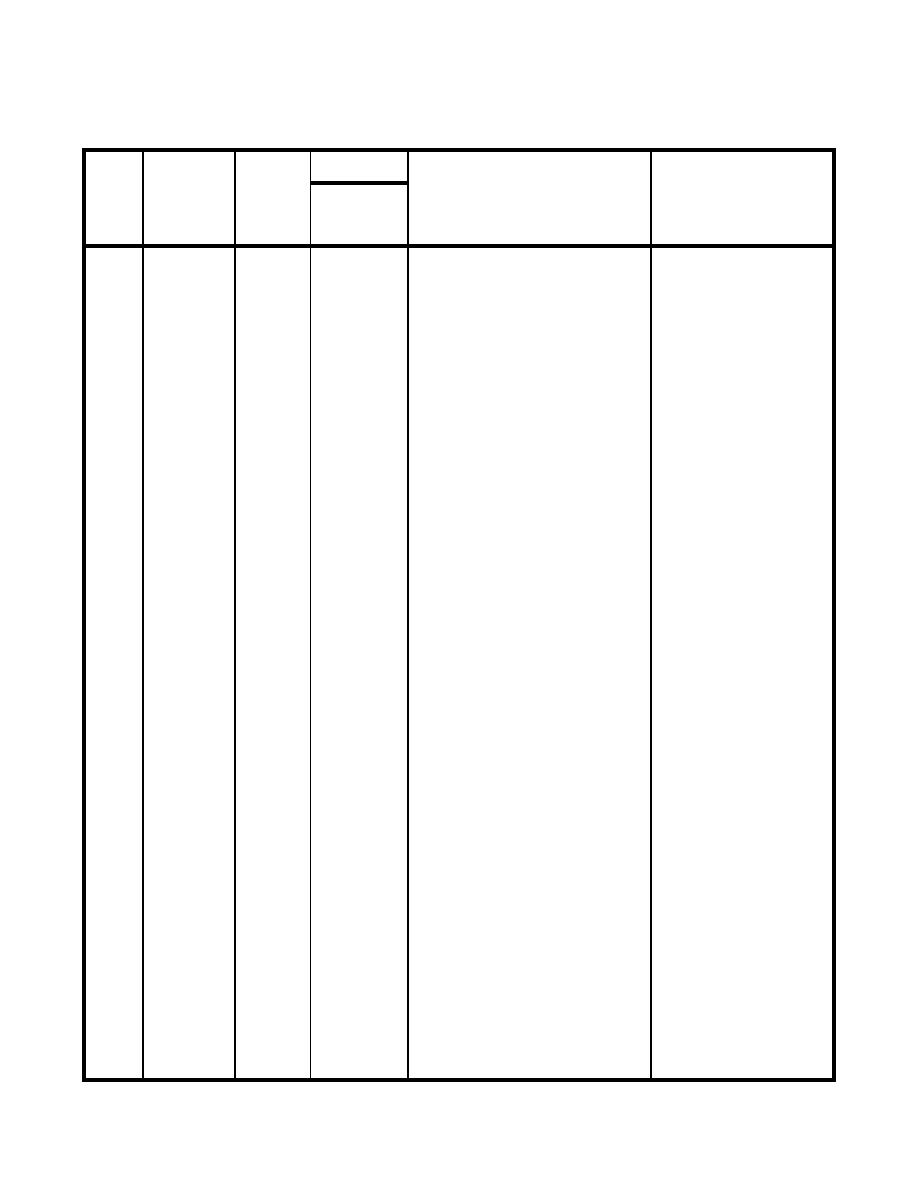

TM 5-3800-205-10-2

Table 1. Preventive Maintenance Checks and

Services (PMCS) for 613CWD Water Distributor - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT FULLY MISSION

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

CAPABLE IF:

a. Check service brakes for pulling, a. Brakes pull, grab or

33

During

Brakes

exhibit unsafe operation.

grabbing or reduced braking capac-

ity.

b. Check parking brake operation with b. Parking brake will not

hold machine.

engine idling and transmission in

high range.

34

During

Steering

Check for smooth, controlled steering Steering is erratic. Any play

without pulling or drifting.

is evident at hitch linkage.

35

During

Drive Train

Monitor tractor operation for unusual

noise or vibrations from engine, trans-

mission, drive shafts, axles, and

wheels.

a. If there is water in tank, monitor a. Any component that is

36

During

Water Dis-

required for mission does

tributor

water distributor for proper opera-

not function. Water leaks

tion of vacuum generator, pump,

that would hinder mission

and tank/piping valves. Watch for

are evident.

evidence of leaks from tank, pump,

valves, drains, and fittings.

b. When suction loading, observe b. Water leaks that would

hinder mission are evi-

whether tank fills within a reason-

dent.

able amount of time. If more than

11 minutes is required to suction

load, perform troubleshooting to

determine cause of problem.

37

During

Overall

Be alert for evidence of fluid leakage.

Class III oil or hydraulic

Leakage

fluid leaks are evident. Any

brake fluid, coolant or fuel

leaks are evident. Water

leaks that would hinder mis-

sion are evident.

With machine fully warmed up, moni- EMS panel or gages indicate

38

During

Instrument

tor EMS indicators, warning lights, an abnormal reading.

Panel

and readings on gages.

(1) Engine coolant temperature

range should be 165F-210F

(74C- 99C).

(2) Torque converter oil tempera-

ture range should be 165F-

265F (74C-129C).

0013 00-28