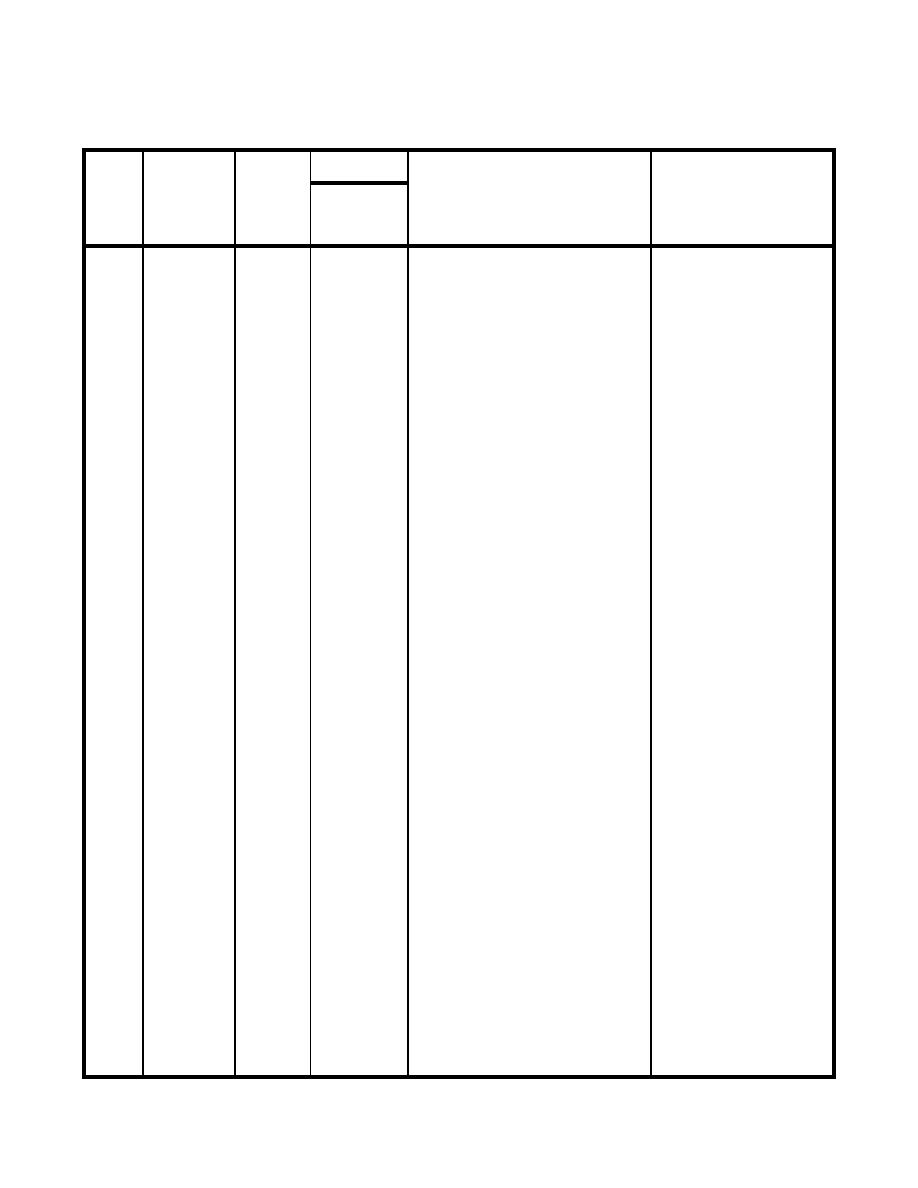

TM 5-3800-205-10-2

Table 1. Preventive Maintenance Checks and

Services (PMCS) for 613CWD Water Distributor - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT FULLY MISSION

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

CAPABLE IF:

Draft Frame a. Check draft frame for cracks, dam- a. Cracks, damage or distor-

44

After

age or distortion.

tion are noted.

and Front of

Tank Assem-

bly

b. Check hydraulic lines and hoses b. Class III hydraulic fluid

leaks are evident. Loose

along draft frame and at tank lift

or missing mounting

cylinders for damage or signs of

hardware is noted.

leaking and secure mounting.

c. Check for damage to quick discon- c. Class III hydraulic fluid

leaks or damage are evi-

nect fittings. Check for condition

dent.

and presence of dust caps.

d. Check fuel lines and air line on right d. Any air or fuel leaks are

evident. Loose or missing

side of draft frame for damage or

mounting hardware or

signs of leaking and secure mount-

damage is evident.

ing.

e. Check electrical wiring and connec- e. Wires or connectors are

damaged.

tors for damage and secure mount-

ing.

f. Visually check mounting brackets f. Damage

that

would

impair operation is evi-

for optional scraper blade assembly

dent, if required for mis-

attachment, at each front corner of

sion.

tank, for damage and loose or miss-

ing mounting hardware.

g. Check under tank for evidence of g. Water leaks that would

water leaks.

hinder mission are evi-

dent.

h. Check three sparging line outlets h. Damage

that

would

impair operation or water

and fittings for damage. Ensure that

leaks that would hinder

camlock cap at outlet of each sparg-

mission are evident.

ing line is securely installed with

camlocks locked, and is not dam-

aged or leaking. Ensure presence of

retaining lanyard.

i. Check front tank drain for damage i. Damage or water leaks

that would hinder mission

or leaks. Ensure camlock cap is

are evident.

securely installed with retaining

lanyard in good condition and cam-

locks locked.

0013 00-32