TM 5-4610-218-34

CHAPTER 5

REPAIR OF CHEMICAL FEED EQUIPMENT

Section I. CHEMICAL SLURRY FEEDER

WARNING

(8) Refer to figure 5-8 and remove the

slurry feeder agitators as illustrated.

Dry cleaning solvent, P-D-680,

c. Disassembly.

used to clean parts, is potentially

(1) Procedures for disassembly of the slurry

dangerous. Avoid repeated and

feeder agitators are illustrated in figure 5-9.

prolonged breathing of the vapors

and skin contact with the liquid.

Do not use near open flame or ex-

slurry feeder shaft, seals and bearings.

cessive heat. Use in a well-venti-

lated area. The flash-point of P-D-

(3) Refer to figure 5-11 and disassemble the

680 is 100-138F (38-59C).

slurry feeder housing.

d. Clean, Inspect and Repair.

5-1. Chemical Slurry Feeder.

(1) Wash all parts in dry cleaning solvent

a. General. The chemical slurry feeder con-

P-D-680 and dry thoroughly.

sists of an aluminum tank divided into two

(2) Inspect for cracks, breaks, wear, dis-

eq ua 1 watertight compartments. The two com-

tortion, and corrosion.

partments are covered with one hinged cover.

Each compartment has four agitators with two

(3) Repair or replace all damaged or de-

measuring cups attached to diametrically op-

fective parts.

posite agitators, a clear plastic window, drain

outlets, collecting funnel, filling connections,

and rate of discharge controller. The chemical

slurry feeder agitators operate from a common

shaft and rotate vertically. Each compartment

functions as a separate unit, permitting two dif-

ferent chemical solutions to be fed at the same

time. The chemical slurry feeder supplies lime-

stone slurry to the erdlator tank and diatomite

slurry to the diatomite dilution tank.

b. Removal.

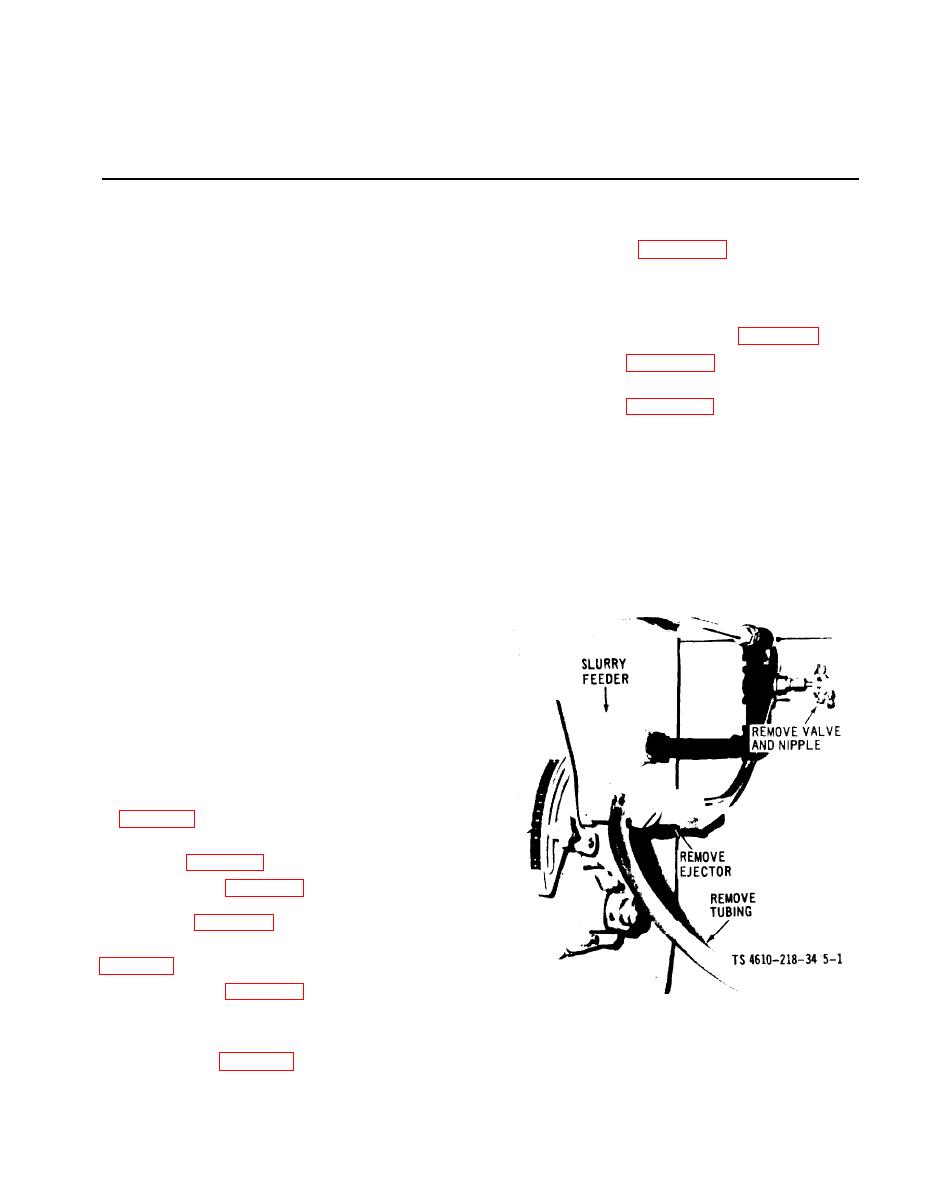

(1) Remove the raw water piping as shown

in figure 5-1.

(2) Remove the filtered water piping as il-

lustrated in figure 5-2.

(3) Refer to figure 5-3 and remove the chain

guard, remove the chain and chain tightener as

illustrated in figure 5-4.

(4) Remove the slip clutch as illustrated in

(5) Refer to figure 5-6 for removal of tubing

between the dilution tank and erdlator tank.

(6) Remove all other parts as necessary.

(7) Refer to figure 5-7 and remove the chem-

Figure 5-1. Slurry Feeder Raw Water Piping, Removal

and Installation

ical slurry feeder tank as illustrated.

5-1