TM 5-4610-218-34

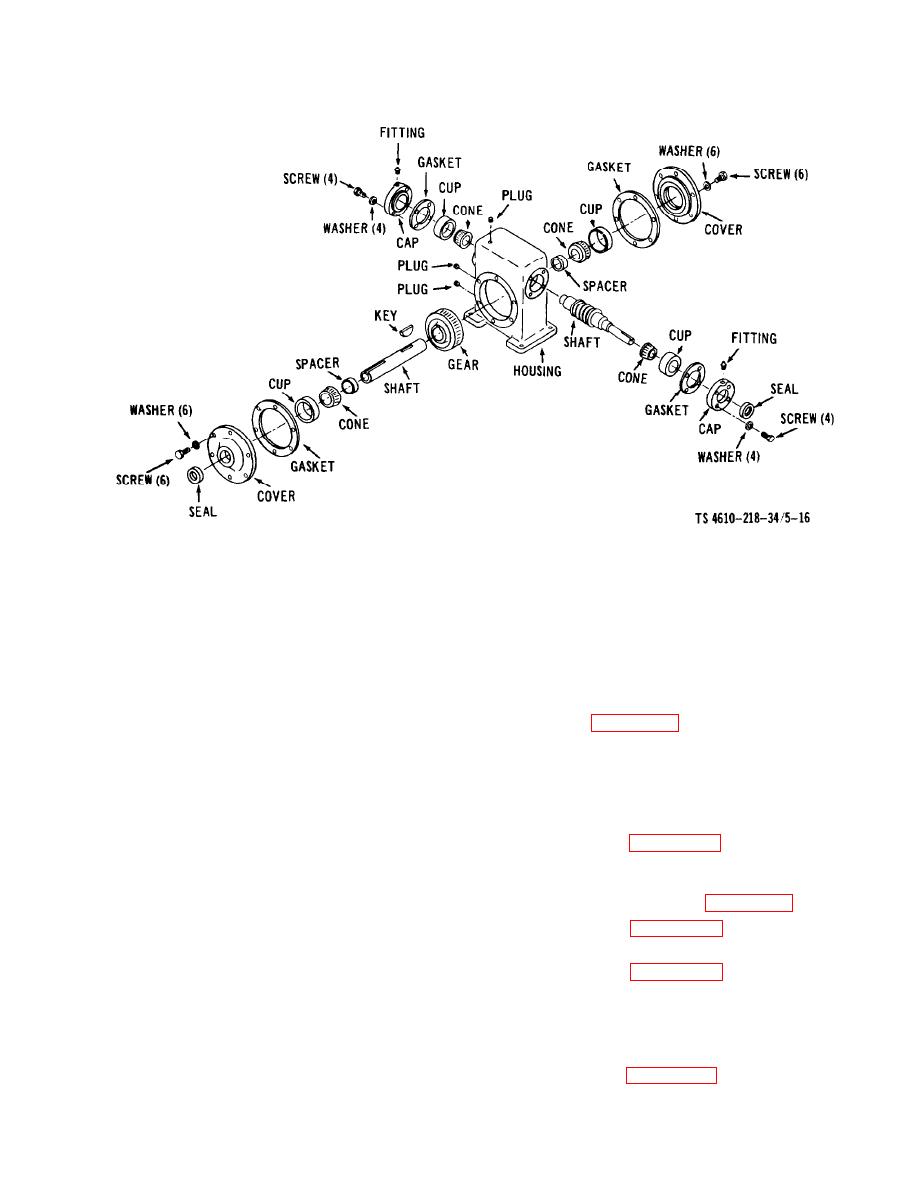

Figure 5-16. Slurry Feeder Speed Reducer, Disassembly and Reassembly

Section IV. CHEMICAL SOLUTION FEEDER

WARNING

(1) Remove the chemical solution feeder as

illustrated in figure 5-17.

Dry cleaning solvent, P-D-680,

used to clean parts, is potentially

(2) Remove the chemical solution feeder di-

dangerous. Avoid repeated and

aphragm pump bodies as illustrated in figure 5-

prolonged breathing of the vapors

17.

and skin contact with the liquid.

c. Disassembly.

Do not use near open flame or ex-

cessive heat. Use in a well-venti-

(1) Refer to figure 5-18 for disassembly of

lated area. The flash-point of P-D-

the drive arms.

680 is 100-138F (38-59C).

(2) Disassemble the solution feeder di-

aphragm pump as shown in figure 5-19.

5-4. Chemical Soultion Feeder.

(3) Refer to figure 5-20 for disassembly of

a. General. The chemical solution feeder con-

the lever arms and push rods.

sists of two diaphragm pumps operated by one

(4) Refer to figure 5-21 for disassembly of

electric motor through a gear reduction mech-

the junction box cover, receptacle, top housing,

anism which transmits the power to recip-

and lever arm shaft.

rocating mechanisms and priming levers. The

pumps operate at approximately 12 strokes per

(5) Remove the gear unit as shown in fig-

minute and each pump operates independently

ure 5-22.

of the other. The gear mechanism and motor are

encased in a cast housing and operate in oil.

gear unit.

b. Removal.

5-13