All Trolleys

For all trolley supported hoists, rail stops must

be installed. These stops must not be positioned to

exert impact force on the hoist but should contact the

end of the trolley side frames.

Low Headroom Trolley

This trolley is packed separately and must be

properly adjusted by the user to fit the runway beam as

follows:

1.

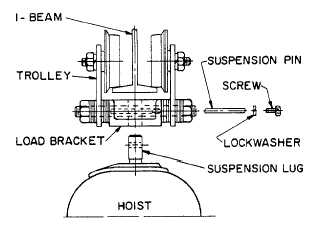

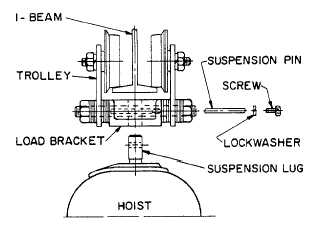

Arrange the side frames, load bracket, spacer

washers and nuts on the suspension bolts

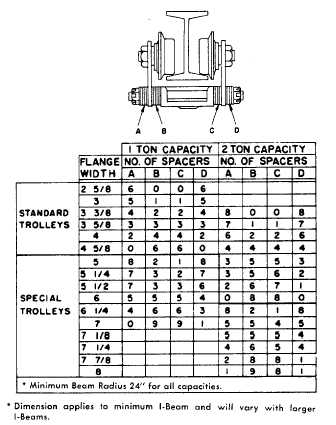

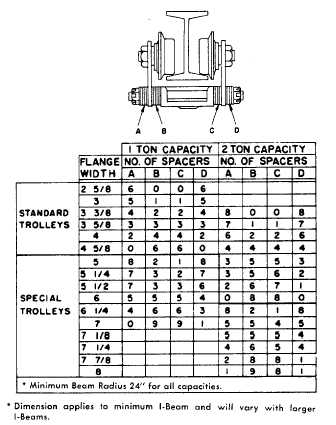

according to Figure 6 and Chart 1. (Warning,

special trolleys shown in chart require special

suspension bolts). Do not assemble cotter pins

to the bolts.

FIGURE 6. LOW HEADROOM LODESTAR TROLLEY.

2.

The number of spacers as given in Chart I is

nominally correct, however, due to the variation

in size encountered on structural steel sections,

it will be necessary in some cases to vary the

number used. Therefore, the distance between

the trolley trackwheel flanges, and the beam

flange width should be measured to determine

the exact distribution of the spacer washers. The

distance between trackwheel flanges should be

1/8" to /';" greater than the width of the beam

flange for straight runway beams and 3/16 to

1/4" if runway system includes sharp curves.

The number of spacer washers between side

frames and load bracket should be the same or

differ only by one spacer to keep the hoist hook

centered under the runway beam.

3.

Install the trolley on beam by sliding one side

frame out far enough to allow the trackwheels to

clear the beam flange.

WARNING:

Deviation

from

CM

washer

recommendations can cause trolley to fall from the

beam. The trolley should be inspected periodically to

assure its continued operation.

CHART I -TROLLEY SIDE FRAME SPACING.

4.

Draw the side frames together and assemble

cotter pins.

FIGURE 7.

ATTACHING HOIST TO TROLLEY.

7