5.

With the trolley mounted on the beam, attach

the hoist by inserting the suspension lug into the trolley

load bracket and inserting the suspension pin through

the load bracket and suspension lug as shown in Figure

7.

6.

Thread the socket head cap screw and

lockwasher into load bracket and tighten securely.

7.

Now, return to page 4 "Power Supply and

Electrical

Connections"

and

complete

the

hoist

installation procedure.

8.

Then with a capacity load on hoist, operate

trolley over the entire length of runway or monorail

system to be sure that the adjustment and operation is

satisfactory. On systems with curves, the edges of the

rail at the curved sections should be kept lightly

lubricated with grease.

Motor Driven Trolley

This trolley is shipped separately and must be

assembled and wired to the hoist by the user. Refer to

the instruction manual packed with the unit.

Enclosed Collectors and Wiring

On low headroom trolley, collectors are to be

installed on each side of trolley. On motor driven

trolley, all collectors are to be installed on one side of

trolley.

Installation Procedure-

1.

Make sure power supply to conductor system is

shut off.

2.

Refer to Figure 9 to determine the proper

mounting position for the collector bars and

brackets.

3.

Attach the brackets by inserting the screws into

tapped holes in the side frames. Tighten screws

securely.

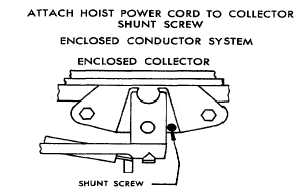

FIGURE 8.

4.

Place an insulator on each collector bar.

5.

Position the bars in the brackets and lock with

set screws. Mount collectors on bar to match

conductor system.

6.

Again refer to Figure 9 position the collectors

on. the bars as shown.

7.

Measure the length of power cable needed t

reach the farthest collector. Allow for

connecting the wire to the collector shunt screw

and cut off the cable.

8.

Strip back the insulation as required and cutoff

Green wire if no ground conductor is installed.

9.

Attach wires to collector's shunt screw ( Fig. 8).

10.

Check installation to make sure that the

collectors make proper contact throughout the

entire length of trolley travel.

11.

Energize conductor system. On three phase

units check for proper direction of hook travel by

following instructions on page 5.

ALTERNATE METHODS OF WIRING

A flexible conductor cable can be used to supply

power to a trolley mounted hoist. The length of

conductor should be adequate for the full travel of

trolley. A long conductor will usually require a clamp or

strain relief (available from factory) fitting at the hoist to

prevent kinking where the conductor enters hoist. To

keep the slack conductor awe from the hoist and load, a

messenger wire system, a counterweighted pulley or a

spring loaded cord reel (available from factory) can be

used.

8