f)

Inspect electric brake friction linings and friction

surfaces for wear, scoring or warpage. Check air

gap between armature and field. If the gap

exceeds 0.045 inch, adjust as described on

page 16.

g)

Inspect the liftwheel pockets for wear as

evidenced by a widening and deepening of the

load end of pocket. That condition will cause

the chain to lift up in pocket and result in binding

between liftwheel and chain guides. Severely

worn liftwheel should be replaced.

h)

Inspect the chain guides for wear or burring

where chain enters hoist. Severely worn guides

should be replaced.

i)

Inspect load chain, chain guides and liftwheel

pockets for clogging with foreign matter which

causes chain to bind. See hoist lubrication of

chain guides, liftwheel, lower sheave wheel and

load chain on page 16.

j)

Inspect trolley trackwheels for external wear on

the tread and flange, and for wear on internal

bearing surfaces as evidenced by a looseness

on the stud.

k)

Inspect collector wheels or collector shoes and

cotter pins for wear. Check the wheels and

studs for corrosion and free turning. Badly worn

parts should be replaced.

l)

Inspect the gasket between the gear housing

and back frame for signs of leaks. Tighten the

screws holding back frame to gear housing. If a

leaking condition persists repack housing and

gears with grease and install a new gasket.

Any deficiencies noted are to be corrected

before the hoist is returned to service. Also, the

external conditions may show the need for

disassembly

to

permit

a

more

detailed

inspection which, in turn, may require the use of

nondestructive type testing.

TESTING:

Prior to initial use, all altered or repaired hoists

or used hoists that have not been operated for the

previous 12 months shall be tested by the user for

proper operation. Test the unit first in the unloaded

state and then with a light load of 50 pounds times the

number load supporting parts of load chain to be sure it

operates properly and the brake holds the load when the

control is released; then test with a * load of 125%/e of

rated capacity.

In addition, hoists in which load sustaining parts

have been replaced shall be tested with * 125C%, of

rated capacity by or under the direction of an appointed

person and a written report prepared for record

purposes.

After this test, the function of the Protector is to

be tested. If the Protector permits lifting a load in

excess of 180%c of rated load it should be replaced.

* If the Protector prevents lifting of a load of 125%c of

rated capacity, reduce load to rated capacity.

NOTE : For additional information on inspection and

testing, refer to Code B30.16 "Overhead Hoists",

obtainable from American National Standards Institute,

1430 Broadway, New York, N. Y. 10018 U.S.A.

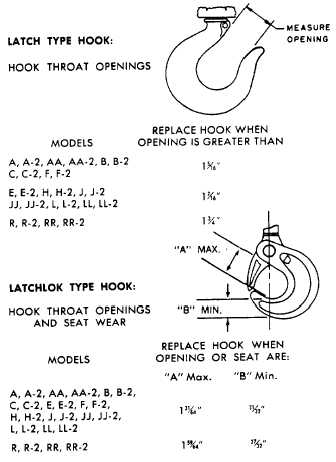

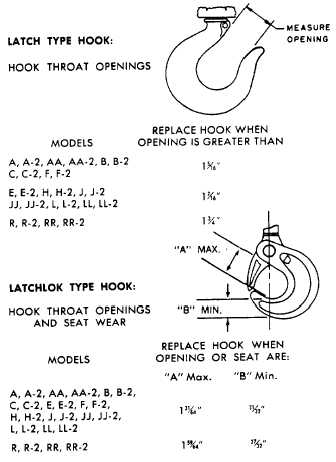

HOOKS:

Hooks damaged from chemicals, deformations

or cracks, or that have more than a 10 degree twist from

the plane of the unbent hook or excessive opening or

seat wear must be replaced.

Also, on latch type hooks, hooks that are

opened and allows the latch to disengage the tip, must

be replaced.

Any hook that is twisted or has excessive throat

opening indicates abuse or overloading of the unit.

Other load sustaining components of the hoist

should be inspected for damage.

Check to assure latch is not damaged or bent.

The charts below should be used to determine

when the hook must be replaced. On latch type hooks,

remove latch to measure opening. Be sure to replace

latch after measurements are completed.

FIGURE 11.

13