CHAPTER I - GENERAL DATA

SECTION I INSTALLATION CHECK POINTS

4 - Electrical

1 - Location

2 - Plumbing

SECTION II EXPLANATION OF REFRIGERATOR

3 - Refrigeration

SYSTEM

4 - Electrical

SECTION I - INSTALLATION CHECK POINTS

Improper

installation

may

cause

irregularity

in

performance. The following points should be checked

and corrected as necessary.

1.

LOCATION

If floor is uneven, level cabinet. For proper ventilation a

minimum of four (4) inches must be allowed on both

sides of cabinet of all Models. The same clearance must

also be provided in the cabinet rear on Models with

condenser or louvers in this area. The location must be

free

from

periodic

freezing

conditions

however

temporary.

2.

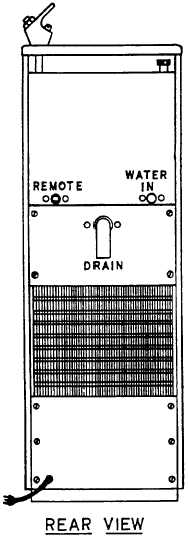

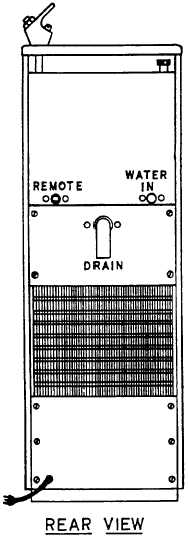

PLUMBING

The cooler drain should be connected to an open or

vented drain. Coolers supplied with a tailpiece require a

slip joint connection. Others require piping to the 1-1/4"

F. P. T. connection. NOTE - there is no internal trap in

cooler.

The 3/8" inlet water connection should be

connected to the building supply line. All water piping

should be clean and rust resistant to prevent fouling of

drinking water. Apply pipe compound sparingly. Avoid

the use of lead or oil based compounds. End of pipe

runs should be avoided. A hand shut-off valve and

union should be installed in supply line near cooler to aid

in later cooler servicing without having to close main

supply valve: Follow local plumbing codes.

Installation of a water strainer between cooler

and shut-off valve is recommended in all cases.

If water pressures exceed 80 lbs. a water

regulator with a setting of 40 lbs. is required in water

supply ahead of cooler.

In areas where "water hammer" is present in the

water supply, install a water regulator and an approved

sealed air chamber to prevent vibration or water line

rupture.

The "Remote" connection can be used as an

auxiliary cold water supply or for draining and flushing

the water system.

3.

REFRIGERATION

The refrigeration system is completely installed, properly

charged with refrigerant, and tested at the factory.

Liquid and suction service shut-off valves, when

provided, are open in shipment.

4.

ELECTRICAL

The water cooler is a factory-wired unit. It must connect

to the type of electrical current and voltage stamped on

the model plate.

3