CHAPTER I

SEC II

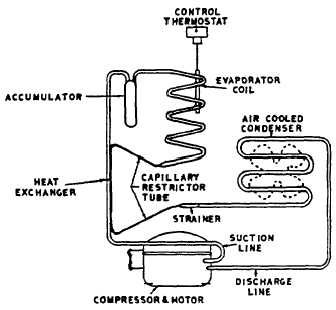

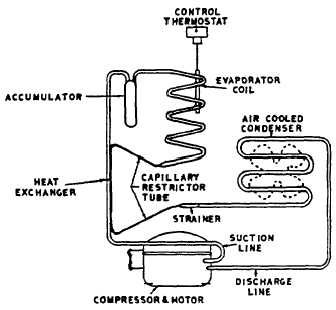

SECTION II - EXPLANATION OF THE REFRIGERATION SYSTEM

SCHEMATIC - REFRIGERATION

When the temperature of the water in the cooler rises

above a predetermined level, contacts of the controlling

thermostat close, causing the refrigeration compressor

and condenser fan motor to start. As the refrigerant

passes through the system a change of state results. It

leaves the compress- or as a hot high pressure vapor

and passes through

the condenser where it is converted to a high pressure

liquid by the removal of heat. The refrigerant then

passes through the strainer and capillary restrictor tube

into the evaporator as a low pressure liquid. In the

evaporator, the refrigerant begins to boil as a cold low

pressure vapor. The compressor suction removes this

vapor and compresses it to a hot high pressure vapor

and the start of a new cycle.

When the desired temperature is attained, the

contacts of the controlling thermostat open causing the

compressor and fan motor to stop. The refrigerant

continues to flow from the condenser, through the

strainer and capillary restrictor tube to the evaporator

due to the pressure differences in the system. This

action will continue until the pressures equalize.

The refrigerant has a tendency to collect and

condense at the coldest part of the system while the

compressor is off. Therefore an accumulator is used to

trap the excess liquid refrigerant. When the compressor

starts, it becomes necessary to draw off the refrigerant

from the accumulator as a vapor, compress and

condense it before cooling can resume.

The refrigeration system of the water cooler is

hermetically

sealed

and

critically

charged

with

refrigerant. Too much or too little refrigerant is

detrimental to the operation. The system has been

dried to a high degree, 10 PPM (Parts Per .Million).

Under normal conditions the refrigeration system should

not be disturbed.

4