BASIC OPERATION:

HYDROSTATIC TRANSMISSION

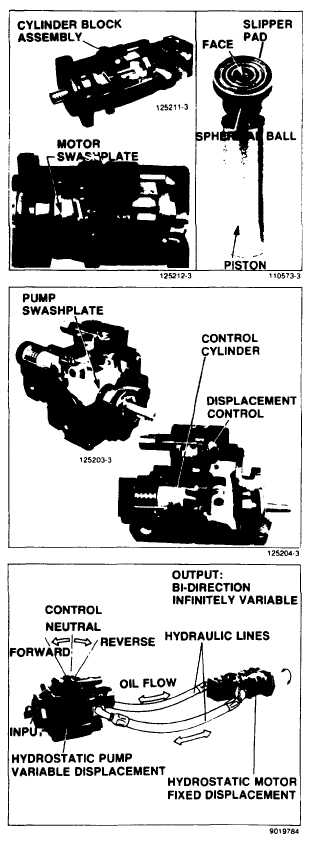

Axial Piston, Slipper Pad Design

Sundstrand hydrostatic pumps and motors are an axial

piston, slipper pad design. There are nine (9) pistons

mounted in the cylinder block. As the cylinder block rotates,

these pistons are forced in and out of their bores by the

angle of the swashplate. This results in a specific amount of

fluid being displaced for every revolution of the cylinder

block. In a pump, the fluid is forced out as the angle of the

swashplate pushes the pistons into the bores. In a motor,

system pressure against the piston causes it to slide down

the inclined face of the swashplate resulting in output

rotation.

The slipper pad attaches to a spherical ball on the end of the

piston forming a ball and socket joint. This allows the

slipper pad to tilt at any angle and make contact with the

swashplate. The face of the slipper pad slides on a

hydrostatic fluid film which uses fluid pressure to balance

internal forces.

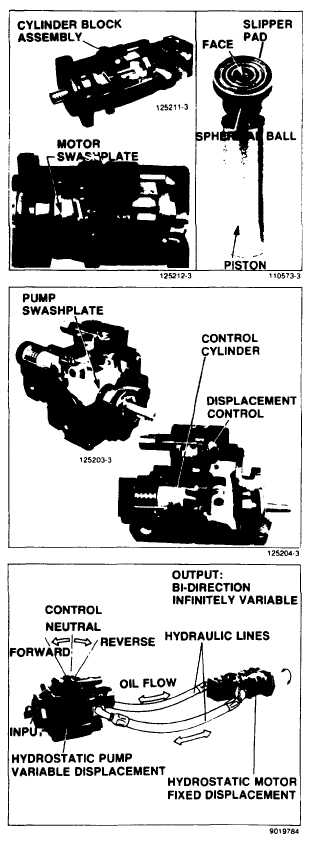

Variable Pump Tilting Swashplate

The variable displacement pumps use a tiltable swashplate

to vary displacement (output flow). The swashplate is

mounted on trunnion bearings and is connected to hydraulic

control (servo) cylinders. The control directs fluid to and

from the servo cylinders causing the swashplate to tilt and

change displacement of the pump. The swashplate can be

tilted in either direction from 0 angle and provide pump flow

in either direction.

Since the angle of the swashplate causes the pistons to

stroke in and out of the cylinder block bores as it is rotated,

changing this angle varies the piston stroke and, therefore,

the amount of fluid being displaced (pumped) to the motor.

This results in a change in the output speed of the motor.

Tilting the swashplate in the opposite direction reverses fluid

flow to the motor and its direction of rotation. Since each

servo control cylinder is spring loaded, loss of control

pressure or charge pressure will cause the swashplate to

return to neutral position.

Hydrostatic Transmission

The

hydrostatic

transmission

consists

of

a

variable

displacement pump connected by hydraulic lines to either a

fixed or variable displacement motor. The pump rotates in

one direction and requires a change of internal parts to

rotate in the opposite direction. The motor rotates in either

direction.

With the hydrostatic transmission. machine control can be

achieved with a single operator control which provides

smooth, stepless speed and direction changes. Placing the

control in neutral (0 swashplate angle) stops transmission

(motor) output which usually eliminates the need for

clutching mechanisms. This feature, however, does not

eliminate the need for a service brake or parking brake.

Page 8