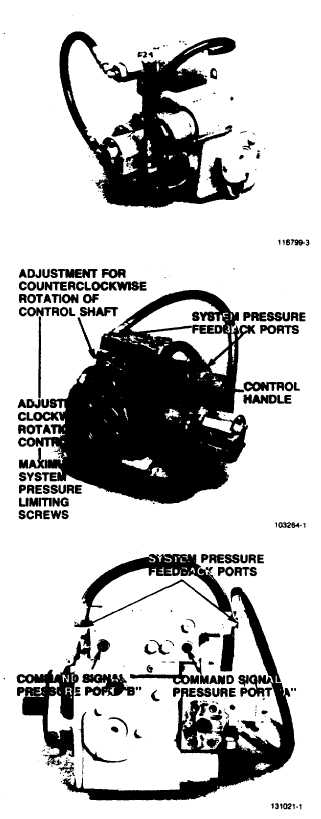

CONTROL ADJUSTMENTS

Manual Variable Pressure Control

Maximum Pressure Adjustment

CAUTION

The following procedure requires the

ability to induce a sufficient load to

create maximum system pressures.

Take the necessary safety precautions

for your application.

1.

Using appropriate adapters, tee two 10,000 PSI

gauges into the system pressure feedback ports of

the control.

2.

Start the prime mover and slowly accelerate to

rated rpm.

CAUTION

Due to linkage bias, etc. there may be

system pressure created immediately

upon starting the prime mover. Take

the necessary safety precautions for

your application.

3.

Stroke the control in one direction and, using a 1/8"

internal hex wrench, adjust the maximum pressure

limiting screw clockwise for less pressure or ,

counterclockwise for more pressure until the

desired pressure reading is achieved. The

adjustment range is 3,000 to 5,000 PSI. Consult

machine specifications for proper pressure setting.

Lock the adjustment screw in place with the 7/16"

hex lock nut; torque to 8-11 ft. lbs.

4.

Stroke the control in the opposite direction and

adjust the other maximum pressure limiting screw

to achieve the desired pressure reading. Lock the

adjustment screw in place.

5.

Stop the prime mover, remove the gauges and

adapters, and reconnect hoses to their original

locations.

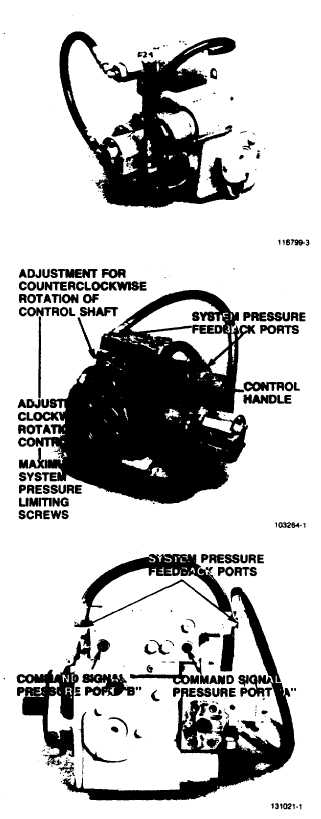

Hydraulic Variable Pressure Control

Maximum Pressure Adjustment

CAUTION

The following procedure require the

ability The following procedure requires

the ability to induce a sufficient load to

create maximum system pressures.

Take the necessary safety precautions

for your application.

1.

Using appropriate adapters, tee two 10,000 PSI

gauges into the system pressure feedback ports of

the control.

2.

Start the prime mover and slowly accelerate to

rated RPM.

Page 22