CONTROL ADJUSTMENTS

3.

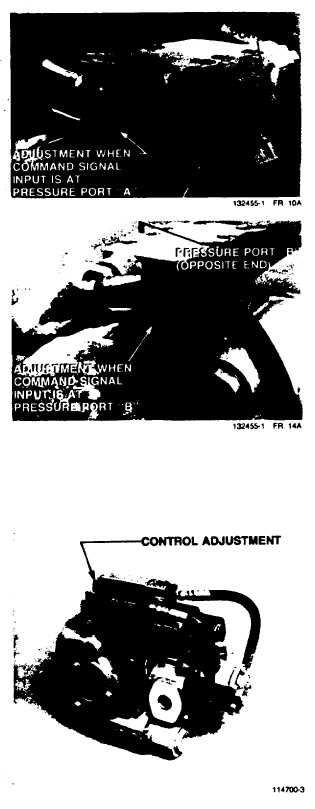

Stroke the command console in the direction which

supplies the command signal to port "A" on the

control (see photo). Stroking the command console

will activate the control and stroke the pump to

create system pressure.

4.

Note the pressure gauge reading. Refer to machine

specifications for proper pressure setting.

5.

Using a 7/16" wrench and 1/8" internal hex wrench,

loosen the locknut and turn adjusting screw CW to

decrease setting or CCW to increase setting. (See

photo with command signal to port "A").

6.

Once desired setting (shown on the pressure gauge)

is obtained hold adjustment screw in place and

tighten locknut.

7.

To adjust the maximum pressure for the opposite

direction slowly stroke the command console in the

direction which supplies the command signal to port

"B" on the control.

8.

Follow Steps 4 through 6 above, but this time turn

the adjustment screw on the opposite end of the

control (see photo with command signal to port "B").

9.

After adjustments have been completed, remove all

gauges.

Pressure Override

Maximum Pressure Adjustment

CAUTION

The following procedure requires the

ability to induce a sufficient load to

create maximum system pressures.

Take the necessary safety precautions

for your application.

1.

Install pressure gauge (10,000 PSI) in the system

pressure gauge port located in the motor manifold

(Ref.

Troubleshooting

Section).

Consult

machine'

specifications for correct pressure setting.

2.

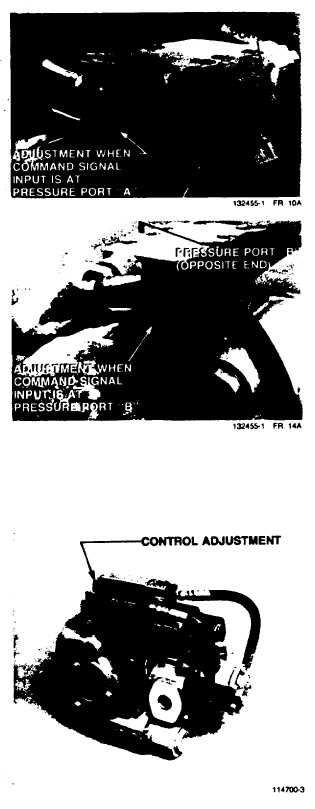

Holding the adjustment screw in place with a 3/16"

internal hex wrench, loosen the locknut (use 9/16"

wrench).

3.

Start the prime mover and load the system. Turn

adjustment screw until desired setting is reached.

The setting will vary approximately 1000 PSI per

turn of screw.

NOTE

System Relief Valves in motor manifold

must be set at least 1000 PSI above

Pressure Override Setting.

4.

Hold adjusting screw in place and torque locknut to

6-10 ft. lbs.

Page 23