WOODWARD PSG GOVERNOR

TESTING AND ADJUSTING

PSG GOVERNOR

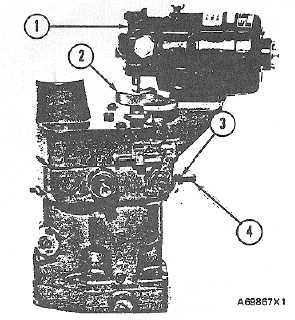

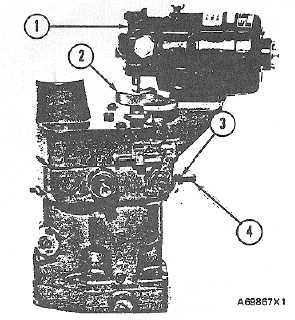

(Typical Illustration)

1. Synchronizing motor. 2. Knurled knob. 3.

Locknut 4. Stop screw.

CHECK SPEED DROOP

The speed droop can be adjusted between zero and

seven percent. The desired speed droop will be different

for different applications. Percent of speed droop is the

percent difference between the engine speed at no load

and full load. To calculate speed droop use the formula:

% of

No load speed-Full load speed X 100 =speed

Full load speed

droop

1.

Get the desired speed droop for the application.

2.

Multiply the full load speed by the desired speed

droop. Add the number from this multiplication

to the full load speed to get the no load speed.

3.

Start the engine and let it run until the

temperature of the coolant is normal.

4.

Adjust the engine speed to get the no load speed

from Step 2.

5.

Connect a known load to the engine. The load

must be less than the full capacity of the engine.

Make a record of the decrease in engine speed.

6.

Make a ratio between the load on the engine and

the full load capacity of the engine. This ratio

must be the same as the ratio between the

decrease in engine speed from Step 5 and the

number from the multiplication in Step 2, For

example:

50 HP (known load)

100 HP (full load capacity)

45 rpm (decrease in engine speed from step 5)

90 rpm (number from multiplication in step 2)

7.

If the ratios are not the same, an adjustment of the

speed droop is necessary. Remove the load and

stop the engine. If the engine speed decreased too

much according to the ratio decrease, the amount

of speed droop. If the decrease in engine speed is

not enough, increase the amount of speed droop.

See SPEED DROOP ADJUSTMENT.

SPEED DROOP ADJUSTMENT

1.

Make a mark on cover (1) to show the original

position of bracket (3). This will show how much a

change in bracket position changes the speed

droop.

2.

Loosen knob (2) that holds bracket (3) and speed

droop lever (4) in position.

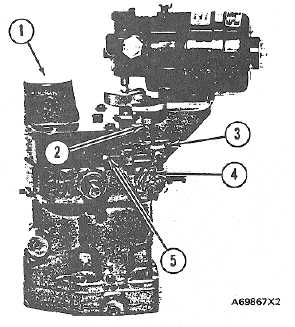

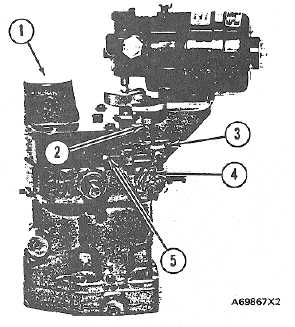

PSG GOVERNOR

(Typical Illustration)

1. Cover. 2. Knob. 3. Bracket 4. Speed droop

lever. 5. Stop screw.

3.

To increase the speed droop turn lever (4)

counterclockwise. To decrease the speed droop

turn lever (4) clockwise.

NOTE: If the lever is turned clockwise beyond the point

where the speed droop is zero the engine will hunt a

large amount and will not get stability.

62