SHUTOFF AND ALARM SYSTEM COMPONENTS

TESTING AND ADJUSTING

SHUTOFF AND ALARM SYSTEMS COMONENTS

CONTACTOR SWITCH FOR OIL PRESSURE

Tools Needed:

3P1564 Pressure Gauge (O to 60 psi).

3B7734 Pipe Nipple, 1/8 in. X 3.5 in.

386483 Cap.

Two 3B7263 Pipe Nipples, 1/8 in. X 2 in.

Two 389389 Shutoff Cock Fittings.

Two 1F9369 Tees.

44914 Tee.

Two 5K3772 Hose Assemblies.

884627 Circuit Tester.

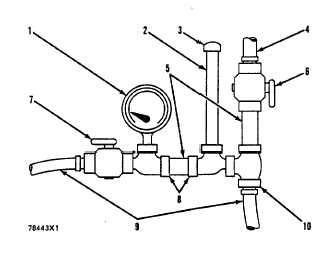

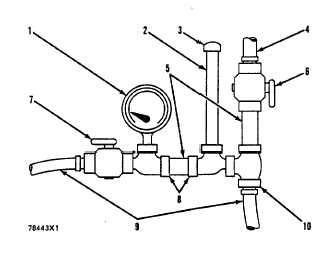

TEST EQUIPMENT

1. 3P1564 Pressure Gauge (0 to 60 psi). 2 3B7734

Pipe Nipple. 3.3B6483 Cap. 4. Oil supply line. 5.

3B7263 Pipe Nipple. 6. 3B9389 Shutoff Cock Fitting.

7. 359389 Shutoff Cock Fitting. 8. 1F9369 Tees.

9.5K3772 Hose Assemblies. 10. 44914 Tee.

Test Procedure

1.

Remove the cover of the contactor switch and

disconnect the wires from the normally closed (B

or Blue) terminal.

2.

Disconnect the oil supply line from the contactor

switch and install the test equipment as shown.

3.

Connect the 5K3772 Hose from tee (10) to the

contactor switch. Put the end of the other

5K3772 Hose in a pan.

4.

Connect the 8S4627 Circuit Tester between the

common terminal and the normally closed

terminal. The light of the circuit tester will be

activated.

5.

Close shutoff fitting (7) and open shutoff fitting

(6).

6.

Look at the pressure gauge, start the engine and

run it at low idle rpm. The light must go out, with

an increase in oil pressure, at the specification of

the switch.

7.

Close shutoff fitting (6) and slowly open shutoff

fitting (7) The light must be activated, with a

decrease in oil pressure, at the specification of

the switch.

8.

Stop the engine.

9.

Connect the wire(s) to the normally closed

terminal.

10.

On contactor switches with a button or a control

knob either push the button or turn the knob to

the OFF position.

11.

Close shutoff fitting (7) and open shutoff fitting

(6).

12.

Start the engine and run it at low idle rpm.

13.

Put a jumper wire between the common terminal

and the normally closed terminal. This will check

the system beyond the contactor switch.

14.

Remove the jumper wire.

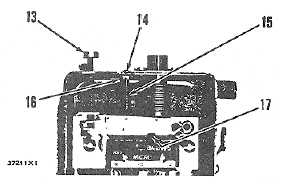

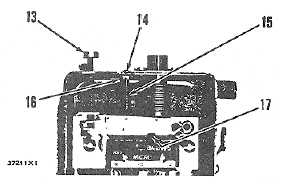

Adjustment of Earlier Micro Switch Type Contactor

1. Loosen locknut (16) and turn adjustment screw (14)

counterclockwise to make a decrease in the tension of

spring (15).

CONTACTOR SWITCH FOR OIL PRESSURE

(Micro Switch Type)

13. Set for start button. 14. Adjustment screw. 15,

Spring. 16 locknut 17. Contact button.

2.

Disconnect the wires from the normally closed

terminal of the switch.

3.

Start the engine and run it at low idle rpm.

4.

Close shutoff fitting (6) and slowly open shutoff

fitting (7) until the pressure gauge shows the

pressure specification at which the switch must

close with a decrease in pressure. Close shutoff

fitting (7).

65