TM 10-4610-246-13

4.20

MAINTENANCE OF RATIO-FEEDER ASSEMBLY

This task covers:

a.

Removal

c.

Adjust

b.

Disassembly

INITIAL SETUP

Tools

Equipment Conditions

Tool Kit, General Mechanics

Suction valve removed (para 3.6).

(Item 1, App. B)

Discharge valve removed (para 3.7).

Parts/Materials

Inlet pipe assembly removed (para 4.16).

Lockwasher (TM 10-4610-246-23P)

Outlet pipe assembly removed (para 4.17).

a. Removal.

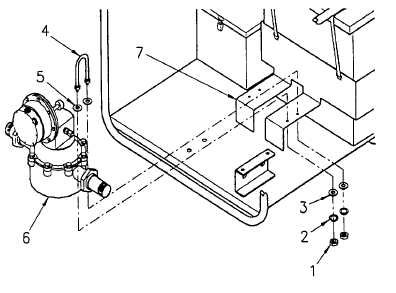

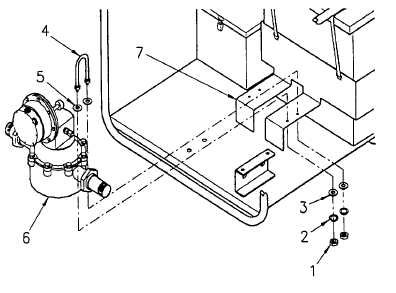

(1) Remove

nuts

(1,

Figure

4-9),

lockwashers (2), flat washers (3), clamp

(4), and flat washers (5) securing ratio-

feeder assembly (6) to frame assembly

(7).

(2) Remove ratio-feeder assembly (6) from

frame assembly (7).

b. Installation.

(1) Position ratio-feeder assembly (6) on

frame assembly (7).

(2) Secure ratio-feeder assembly (6) with

flat washers (5), clamps (4), flat washers

(3), new lockwashers (2), and nuts (1).

c. Adjust.

NOTE

Figure 4-9. Ratio-Feeder Assembly

Ratio-feeder assembly must be adjusted

while unit is in operation. Turn stroke

adjusting knob only during turning stroke.

(1) Turn ratio-feeder assembly completely

off by turning stroke adjusting knob (1,

Figure 4-10) clockwise as far as

possible, while pump is in operation.

4-18