TM 10-4320-317-13

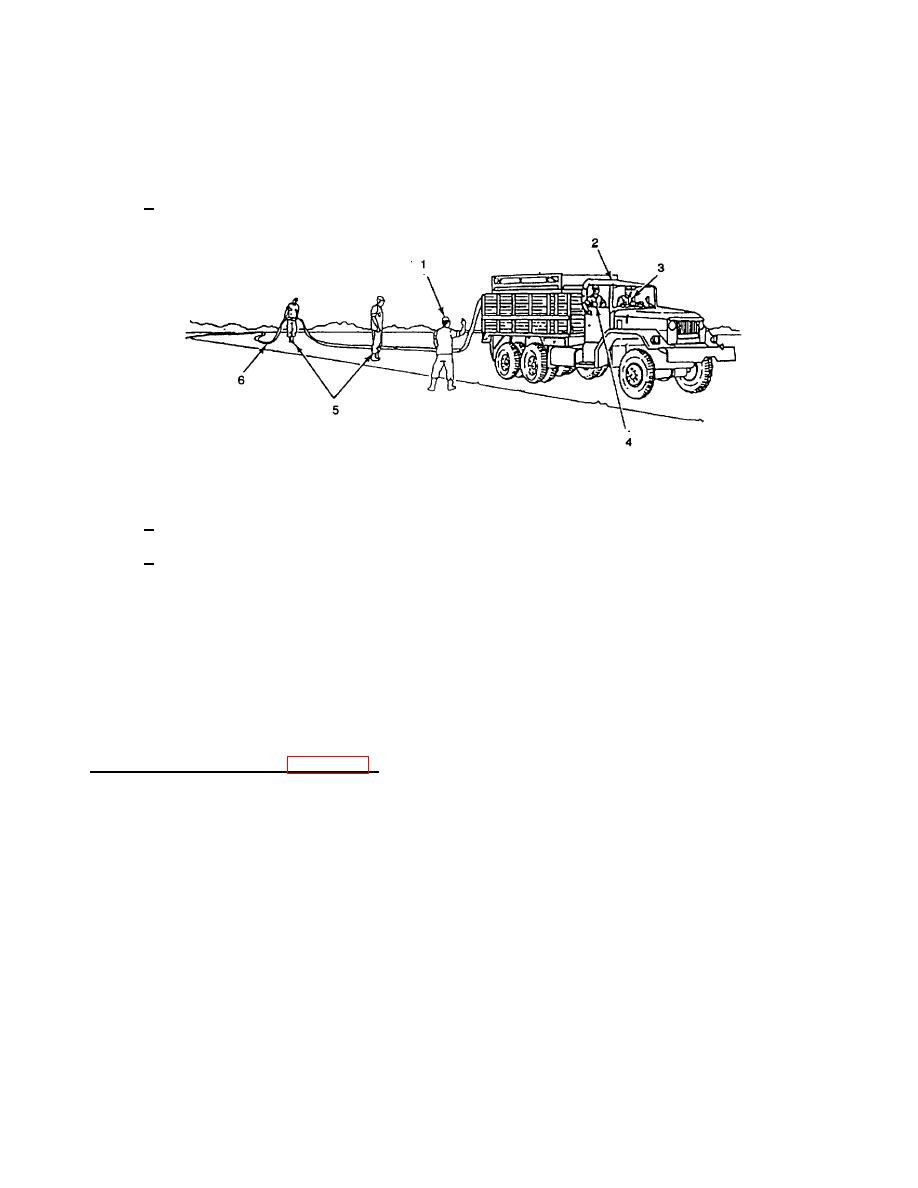

(c) An assistant driver (4) is needed to observe hose-laying operation, tell driver (3) to speed up, slow down, or

stop truck (2) depending on needs of the linewalkers (5) straightening and repositioning hoseline (6). He

must also observe hose for catching or binding as it flakes out of box.

(d) A minimum of two linewalkers (5) are needed to follow behind each truck (2) and perform following tasks:

1

Straighten out kinks or bends in hoseline.

Figure 2-6. Hose-Laying Operations

2

Remove small obstructions, branches, and sharp rocks which can damage hoseline.

3

Check that swivel joint is installed at every 1000 ft (305 m) connection.

(5) Empty hose is easily blown by strong winds, causing damage to installations and equipment. To avoid high

wind problems, fill newly-laid hose with water as soon as possible. Once lead pump and first boost pump are

connected by hoseline, see operating procedures and fill hoseline.

(6) During hose-laying operations, it is essential that operators at pumping stations and storage assemblies

communicate with each other and with hose-laying crews. If a problem develops with the hose-laying

operation, immediately notify operators who are packing hoseline. If a problem occurs when hoseline is

packed, immediately notify hose-laying supervisor and other operators.

b.

Boltless Coupling Installation (Figure 2-7). Follow this procedure when using a boltless coupling to connect two

grooved TWDS components.

NOTE

This is a general procedure for installation of 6-inch boltless couplings

throughout the system. Follow this procedure when using a boltless

coupling to connect two TWDS components.

In some cases, boltless couplings are part of a hose assembly and

must be installed over the hose end for packing purposes. When step

instructs to do so, follow this procedure when installing a boltless coupling

over the end of a hose.

2-27