TM 10-4610-239-24

TM 08580B-24/3

Table 3-1. Direct Support Troubleshooting - Continued

Malfunction

Test or Inspection

Corrective Action

BOOSTER PUMP ASSEMBLY - Continued

PUMP ELECTRIC MOTOR FAILS TO START WHEN BOOSTER PUMP SWITCH IS SET TO START - Continued

Step 4.

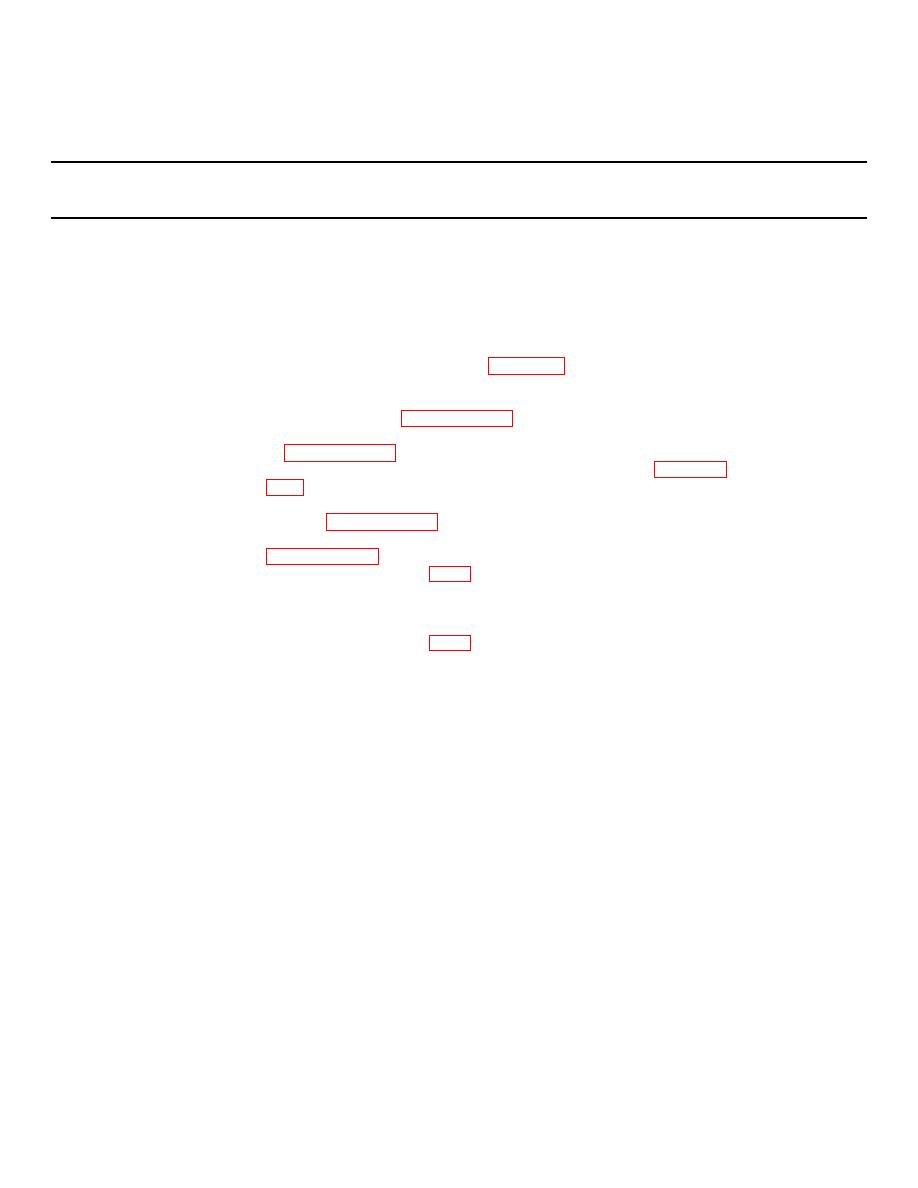

Shut down ROWPU. Refer to TM 10-4610-239-10. Shut down power. Refer to

generator manual. Set BOOSTER PUMP switch to RUN position. Refer to

booster pump assembly support diagram figure 3-4. Check continuity

point-to-point between test points A andB through S6-2 and S6-7.

If all checks indicate continuity except across terminals 2 and 3 of K6,

repair K6. Refer to paragraph 3-49.

If there is no continuity through other sections of K6, repair K6. Refer

If there is no continuity through S6, replace S6. Refer to paragraph

If there is no continuity through a wiring harness, repair wiring harness.

Refer to paragraph 3-39.

If there is no continuity through a cable, repair cable assembly. Refer to

Step 5.

Refer to schematic diagram figure FO-3. Check for 208 V ac at K6 between

terminal pairs T1 and T2, T2 and T3, and T1 and T3.

If 208 V ac is not present on all terminal pairs, go to step 6.

If 208 V ac is present on all terminal pairs, go to step 9.

Step 6.

Refer to schematic diagram figure FO-3. Check for 208 V ac at K6 between

terminal pairs on the top screw of each heater; left to center, center to right, and

left to right.

If 208 V ac is not present on all terminals pairs, go to step 10.

If 208 V ac is present on all terminal pairs, shut down ROWPU. Refer

to TM 10-4610-239-10. Shut down power. Refer to generator manual.

Remove screws and three heaters. Replace heaters that have damaged

elements. Start ROWPU. Refer to TM 10-4610-239-10. Repeat step 5.

If 208 V ac is not present on all terminal pairs after repeating step 5, go

to step 7.

If 208 V ac is present on all terminal pairs after repeating step 5,

malfunction caused by faulty heater elements has been corrected.

3-21