TM 10-4610-239-24

TM 08580B-24/3

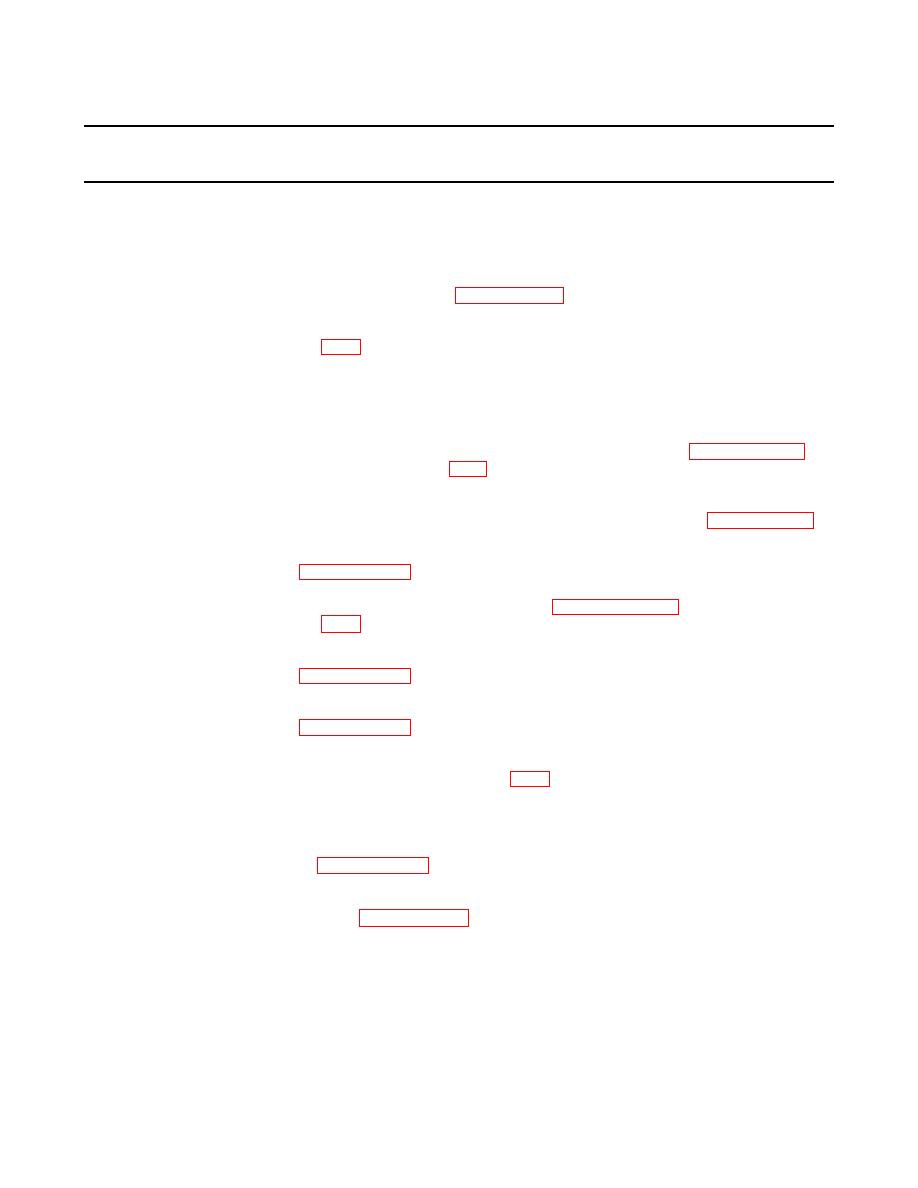

Table 3-1. Direct Support Troubleshooting - Continued

Malfunction

Test or Inspection

Corrective Action

BACKWASH PUMP ASSEMBLY - Continued

2. PUMP ELECTRIC MOTOR FAILS TO START WHEN ELEMENT CLEANING SWITCH IS SET TO START -

Continued

If no motor controller terminal is shorted to ground terminal El, replace motor

controller K2. Refer to paragraph 3-46.

Step 9.

Disconnect backwash pump cable connector P2 from ROWPU. Refer to schematic

diagram figure FO-3. Check for short circuits between P2-D, and P2-A, P2-B, and P2-C.

If no pin is shorted to P2-D, go to step 10.

If any pin is shorted to P2-D, go to step 11.

Step 10.

Remove receptacle connector J2 from electrical junction box. Refer to paragraph 3-37.

Refer to schematic diagram figure FO-3. Check for a short circuit between J2-D and motor

controller K2 terminals T1, T2, and T3.

If any terminal is shorted to J2-D, repair cable W6. Refer to paragraph 3-17.

If no terminal is shorted to J2-D, replace receptacle connector J2. Refer to

Step 11.

Remove backwash pump cable assembly. Refer to paragraph 2-138. Refer to schematic

diagram figure FO-3. Check for short circuits between P2-D and P2-A, P2-B, and P2-C.

If any pin is shorted to P2-D, repair backwash pump cable assembly. Refer to

If no pin is shorted to P2-D, repair backwash pump electric motor. Refer to

Step 12.

Shut down ROWPU. Refer to TM 10-4610-239-10. Shut down power. Refer to generator

manual. Refer to schematic diagram figure FO-3. Check continuity between motor

controller K2 terminals L1, L2, and L3 and receptacle connector J1 pins A, B, and C

respectively.

If all three measurements indicate continuity, repair motor controller K2. Refer

If all three measurements do not indicate continuity, repair wiring harness W5.

Refer to paragraph 3-39.

3-71