ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

0034 00

TROUBLESHOOTING PROCEDURES

UNIT TROUBLESHOOTING PROCEDURES TACTICAL WATER

PURIFICATION SYSTEM (TWPS)

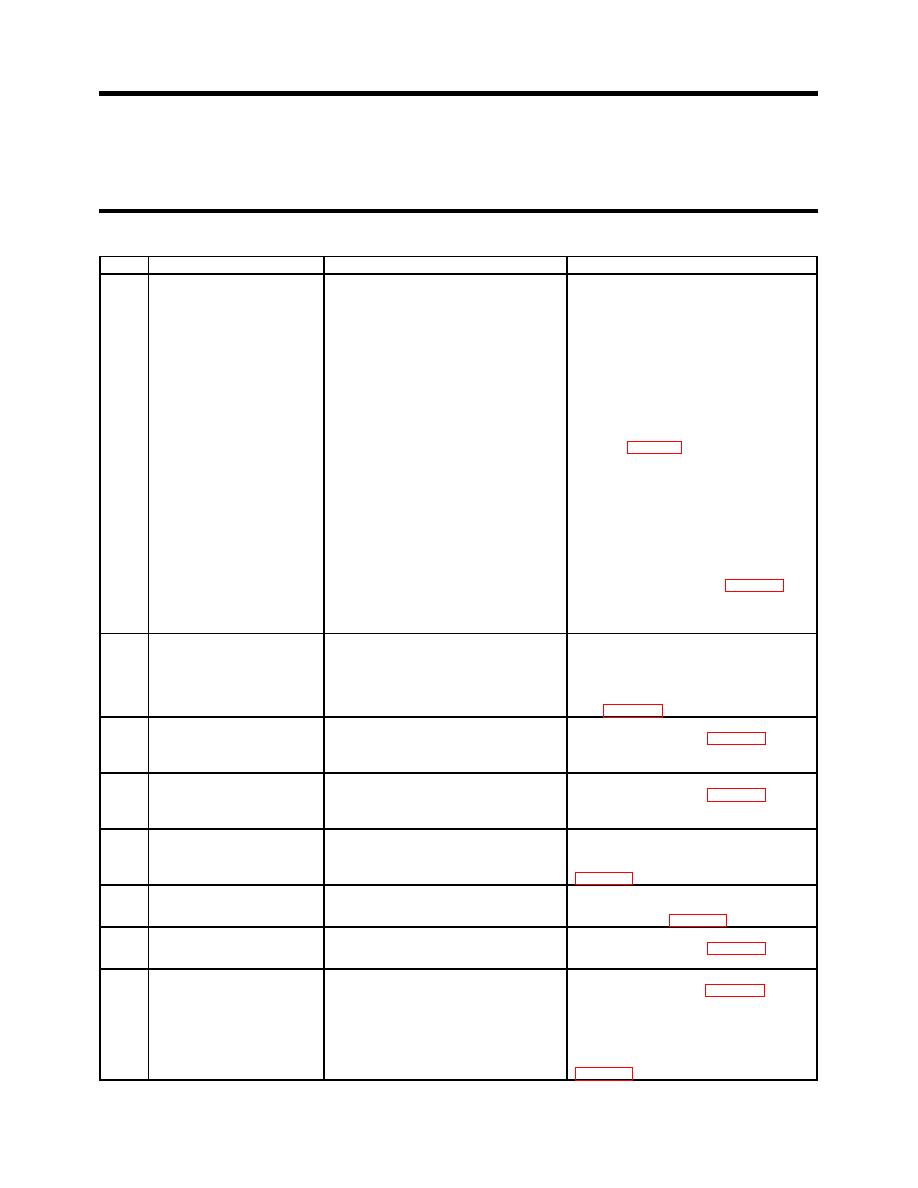

Table 10. Air Compressor Troubleshooting Continued.

ITEM

MALFUNCTION

POSSIBLE CAUSES

CORRECTIVE ACTION

2

Compressor does not start

Continuing, if channel 14 is ON:

cont.

with switch in Auto and no

pressure. Switch light is

At first start up, circuit breaker CB133

Set CB to On position (black handle up).

OFF.

manually set to OFF position (black

Or

handle down).

Compressor was running and

Motor contactor M510 failure corroded

Open the PDP. Set the Main breaker to

stopped at a pressure well

main contacts.

ON. Set the air compressor switch to Auto.

below 975 psig. Switch light

Check the voltage between the contactor

is OFF (continued).

output terminals and ground. If one or

more do not show voltage, replace the

contactor (WP0063).

Electrical wiring or compressor motor

Set the Main Circuit Breaker to OFF. Open

failure.

the motor terminal box and remove the

insulators from the wire connections. With

the wires spread apart, set the Main Circuit

Breaker to ON and set the Air Compressor

switch to AUTO. Measure the voltage from

each phase wire to ground.

1) If voltage is found at all three, replace

the compressor motor (WP 0056).

2) If voltage is not found at a wire,

troubleshoot the wire run for the

location of the open circuit.

nd

If the safety valve on the 2 stage head is

3

Safety valves between

Stage head valves not closing properly.

st

releasing, replace the 1 stage valve head.

individual stages releasing

If the safety valve on the intermediate filter

pressure.

nd

is releasing, replace the 2 stage valve

head (WP 0056).

4

No flow observed in

Air trapped in oil pump.

Bleed lubrication system (WP 0042).

pressurized oil sight glass

after oil change.

5

Pressurized oil sight glass

Air trapped in pressurized oil system.

Bleed lubrication system (WP 0042).

exhibits air bubbles after oil

change.

6

Oil is foamy and milk colored.

Water in the oil from worn cylinder rings.

Change the oil. Continue operation.

Replace compressor when time allows

7

High oil consumption.

Cylinder rings worn.

Continue operation. Replace compressor

when time allows (WP 0056).

8

Air compressor has no oil

Air trapped in oil pump.

Bleed lubrication system (WP 0042).

pressure.

9

Drive belt has rolled over

Loose or worn belt

Replace belt and tighten (WP 0056).

Check motor mount.

Loose motor mount

Check motor mounting plate bolts. Be sure

they are tight. If loose, be sure that the

motor and compressor sheaves are aligned

0034 00-35