ARMY TM 10-4610-309-14

MARINE CORPS TM10802A-14/1

0036 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

OPERATOR MAINTENANCE PROCEDURES

SERVICE UPON RECEIPT

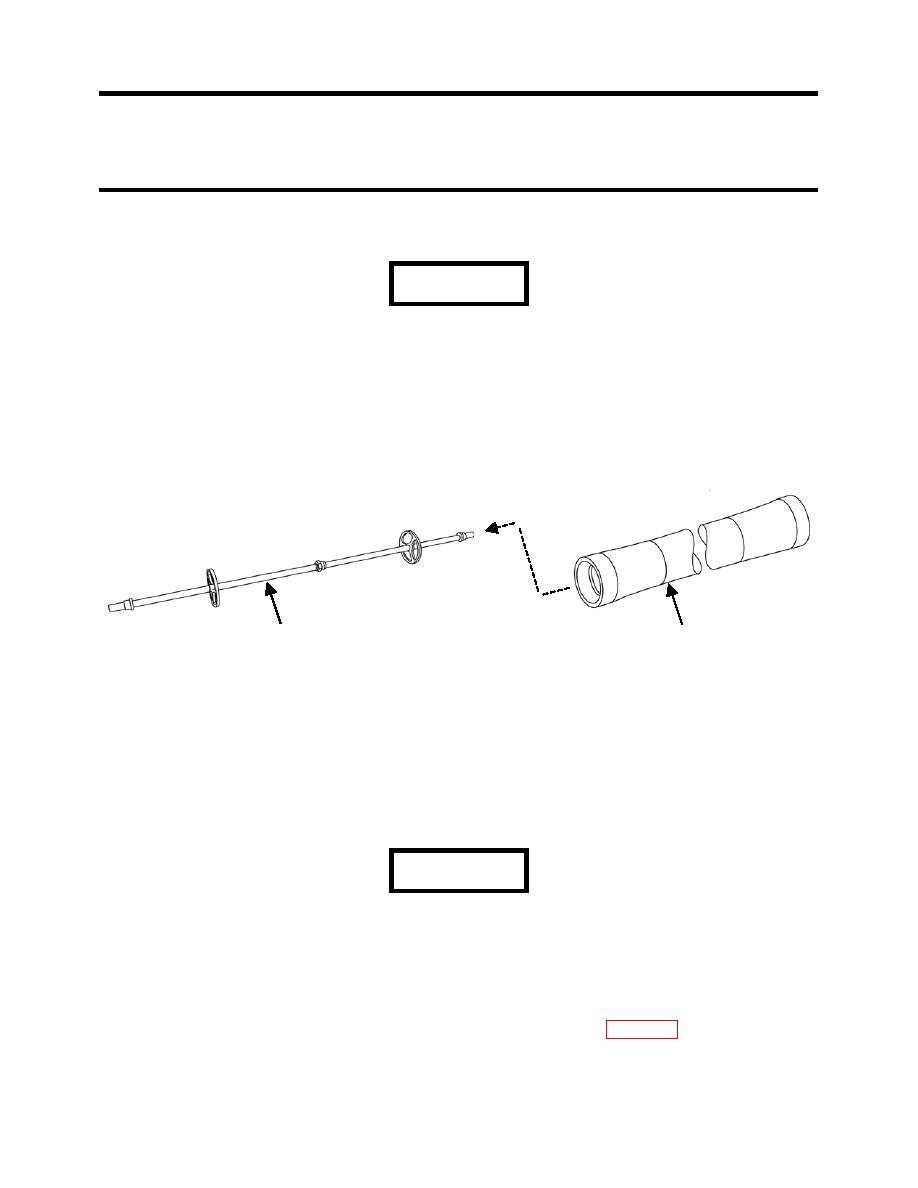

3. Remove the RO element simulator from the vessel (see Figure 3).

WARNING

Damage or scratches deeper than the paint can result in failure of the vessel wall

during operation. Do not scratch or damage the vessel bore when removing the

simulator or installing elements. Failure to observe this warning can result in

injury or death or damage to equipment from catastrophic failure of the vessel

under high pressure during operation.

a. Clean off any excess lubricant from the inside of the vessel before removing the

simulator.

b. Pull the simulator out of the vessel at the end closest to the operator station.

RO ELEMENT SIMULATOR

RO VESSEL

Figure 3. RO Element Simulator Removal.

4. Clean and inspect the inside of the vessel as follows:

a. Flush out the vessel with clean water to remove any debris.

b. Inspect the inside surface of the vessel for corrosion, deposits or other foreign matter. If

any are found, clean the surface as follows:

1) Using a scouring pad and a mild soap solution, clean each end of the vessel liner

surface up to eight in. from each end of the vessel.

2) Rinse away all loosened deposits from the inside of the vessel.

WARNING

Do not attempt to repair a fiberglass vessel. If a vessel has damage or scratches

deeper than the paint, the vessel should be replaced. Failure to observe this

warning can result in injury or death or damage to equipment from catastrophic

failure of the vessel under high pressure during operation.

c.

Examine the inside of the vessel for scratches or imperfections that may affect the

sealing ability of the end cap or element seals. If severe scratches or damage are found,

notify Direct Support to replace the vessel as described in WP 0070, Reverse Osmosis

System Direct Support Maintenance Procedures under the heading RO Vessel

Replacement.

0036 00-7