ARMY TM 10-4610-309-14

MARINE CORPS TM10802A-14/1

0036 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

OPERATOR MAINTENANCE PROCEDURES

SERVICE UPON RECEIPT

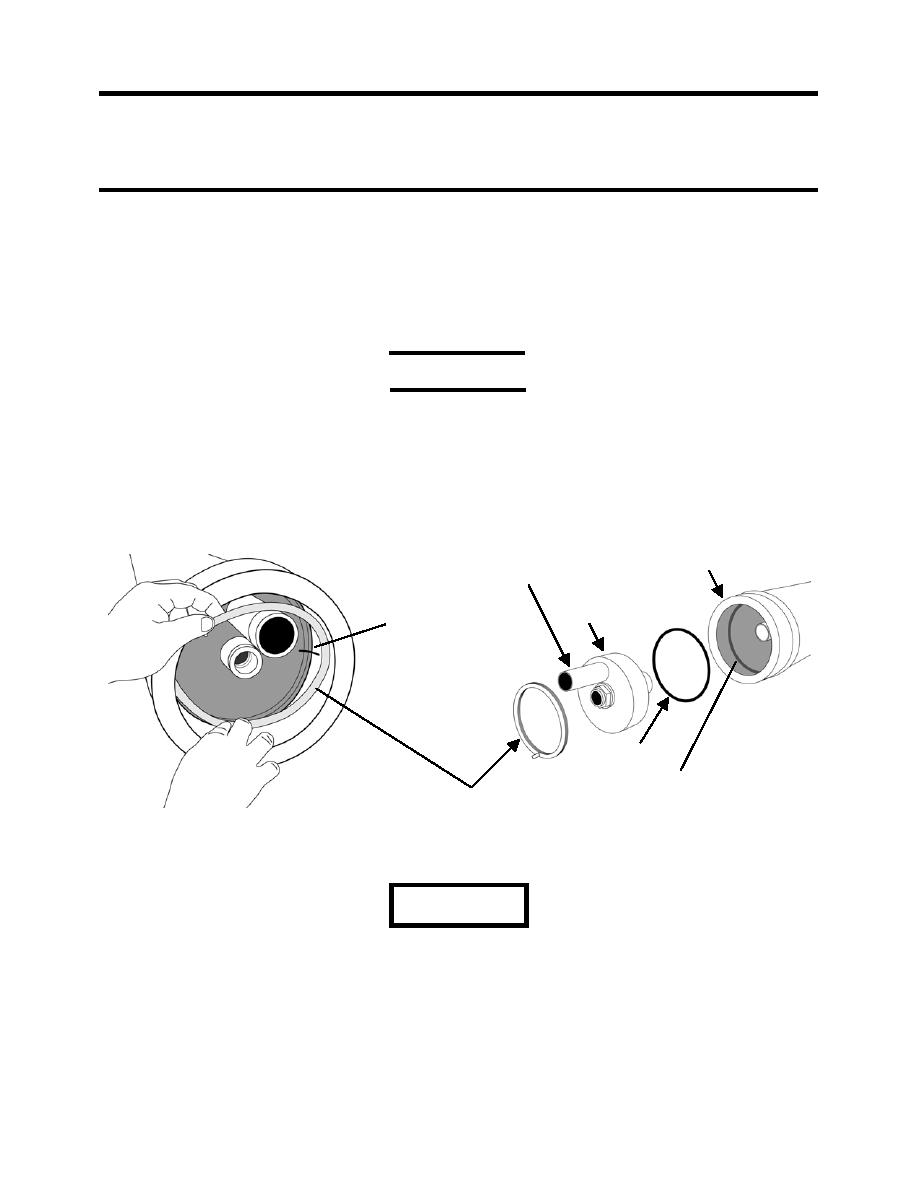

6. Install the upstream end cap assembly as follows (see Figure 6):

a. Apply glycerin inside the vessel from behind the retaining ring groove to about one-half

in. into the vessel.

b. Cover the entire end cap seal with a thin layer of glycerin. Make sure no dirt

contaminates the glycerin.

c. Align the orientation mark that you put on the end cap assembly during removal with the

orientation mark that you put on the vessel.

CAUTION

Do not rotate the end cap assembly after inserting it into the vessel. Failure to

observe this caution may cause the end cap seal to bind or become detached.

d. Hold the end cap assembly square to the axis of the vessel and slide it straight into the

vessel until a slight resistance is felt.

e. Using both hands, push the end cap in as far as it will go (a forceful thrust may be

needed to push the end cap seal into the vessel bore.) When the end cap is in the

correct position, the entire retaining ring groove will be exposed.

RO VESSEL

FEED/REJECT PORT

END CAP

ORIENTATION LINE

END CAP SEAL

RETAINING RING GROOVE

RETAINING RING

Figure 6. RO Vessel End Cap and Retaining Ring Installation.

WARNING

Potential catastrophic failure point. The retaining ring must be correctly installed.

Failure to observe this warning can result in explosive end cap failure when the

vessel is pressurized which, in turn, can cause death, serious injury, and/or severe

equipment damage.

f.

Place the tip of the retaining ring into the groove, then slide your fingers around the ring

pushing it into the groove as you go until the entire ring is in the groove (see Figure 6).

g. Verify that the retaining ring is fully seated in the groove before proceeding.

0036 00-10